جدول المحتويات

تبديل1. المقدمة

When you turn on a tap at home, water flows effortlessly—a simple convenience we often take for granted.

Yet, behind your walls lies a complex engineering feat: an intricate network of pipes and fittings designed to withstand constant pressure, resist chemical corrosion, and deliver safe, clean water for decades.

In the evolution of modern plumbing, traditional materials like copper or rigid PVC are increasingly being replaced by more advanced solutions.

Leading this charge is the PPR (Polypropylene Random Copolymer) piping system. Technically classified as Type 3 Polypropylene according to ISO 15874 standards, PPR is not just “another plastic pipe.” It is a high-performance thermoplastic engineered at a molecular level.

By “randomly” incorporating ethylene into the polypropylene chain, manufacturers have created a material that balances flexibility with high-impact strength and exceptional thermal resistance.

Unlike traditional systems that rely on mechanical threads or chemical glues—which often become the “weakest link” over time—a PPR system works as a fully integrated, homogenous network.

Through a process known as heat fusion, the pipes and fittings are molecularly bonded to become a single, continuous piece. This creates a seamless, leak-proof connection that is capable of maintaining system integrity even under demanding conditions.

For procurement managers and engineers, choosing the right piping system isn’t just about the material—it’s about understanding how it integrates into the overall project.

To provide a clearer perspective for your next selection, we will explore the material science behind PPR, how its ‘one-body’ fusion principle impacts long-term maintenance, and the practical factors that make it a reliable choice for modern plumbing and industrial applications.

This Ultimate Guide to PPR Piping Systems is designed to provide engineers, contractors, and procurement professionals with a comprehensive, 360-degree technical perspective.

We will navigate through the complexities of the system across the following key pillars:

The Material Science (Chapter 2): We go beneath the surface to explore the molecular structure of Type 3 Random Copolymer, explaining how its unique resin composition ensures superior creep resistance and a 50-year service life.

Engineering Specifications (Chapter 3): We decode the critical relationship between SDR (Standard Dimension Ratio) and PN (Pressure Nominal), providing essential logic for pressure-temperature de-rating in real-world environments.

The Physics of Installation (Chapter 4): We move beyond simple “joining” to analyze the science of Thermal Socket Fusion, detailing how molecular interdiffusion creates a homogenous, leak-proof system.

Versatile Applications (Chapter 5): We demonstrate the PPR “multitool” in action, from high-hygiene potable water lines to energy-efficient HVAC chilled water loops and industrial-grade air systems.

FAQs (Chapter 6): We address the industry’s most pressing questions, clarifying the technical distinctions between PPR, PE-RT, and PEX to ensure the right material is selected for every unique challenge.

2. What Is a PPR Piping System?

A PPR piping system is a high-performance solution engineered from Polypropylene Random Copolymer (PP-R). It is a thermoplastic material specifically designed to combine mechanical strength, long-term flexibility, and exceptional resistance to both thermal and chemical corrosion.

Unlike traditional plumbing setups that often mix disparate materials—such as copper, PVC, or galvanized iron—a PPR system is designed as a fully integrated, homogenous network.

In this system, every component, from the main risers to the smallest elbow, shares the same chemical properties. This ensures absolute compatibility, consistent thermal expansion rates, and uniform performance throughout the entire building infrastructure.

The reliability of a PPR system is determined long before the pipes reach the construction site. It begins at the molecular level and is dictated by the purity of the raw resin.

The Evolution of Polypropylene: Three Generations

Under the international standard ISO 15874, Polypropylene (PP) is categorized into three generations. Understanding these differences is the first step in professional risk management:

- النوع الأول: PP-H (Homopolymer): Consisting of a single propylene monomer, it offers high stiffness but is inherently brittle, especially at low temperatures. It lacks the long-term heat resistance required for pressurized plumbing.

- النوع الثاني: PP-B (Block Copolymer): This version arranges ethylene “blocks” in a regular pattern. While it improves impact resistance in cold weather, its “creep strength” is insufficient for long-term high-temperature stress.

- النوع 3: PP-R (Random Copolymer): The industry “Gold Standard.” By randomly inserting ethylene molecules (3%–5% by mass) into the polypropylene backbone, it disrupts the crystalline structure to achieve an ideal balance of toughness and thermal stability.

The “Random” Advantage: Creep Strength and Toughness

The molecular-level “disorder” created by random copolymerization grants the system two critical engineering properties:

- Enhanced Creep Rupture Strength: PPR can withstand constant internal pressure at high temperatures for over 50 years without undergoing brittle failure.

- Dynamic Resilience: The material remains flexible enough to absorb water hammer (pressure surges) while maintaining the structural rigidity needed for vertical risers.

Engineering Parameters: HMW and MFR

Even within Type 3 materials, quality varies based on the polymerization precision:

- High Molecular Weight (HMW): Premium PPR features a high molecular weight and narrow distribution (MWD). This enhances the Environmental

- Stress Cracking Resistance (ESCR), preventing micro-cracks from forming when the pipe is exposed to household chemicals or sudden surges.

- Melt Flow Rate (MFR) Stability: A stable MFR ensures that during extrusion, the pipe wall thickness remains perfectly uniform. This prevents “thin spots” that act as invisible failure points under long-term pressure.

- Distribution Precision: If ethylene is not distributed perfectly, “rich spots” can form, leading to localized weak points. Top-tier manufacturers use advanced gas-phase or slurry-loop reactors to ensure chemical consistency in every millimeter of the pipe.

The Stabilization Package and Safety

A professional-grade PPR system is more than just resin; it is a stabilized chemical network.

- Antioxidants (AO): Because PPR is a thermoplastic, it is susceptible to thermal-oxidative degradation. Premium systems utilize high-performance antioxidant chains to prevent the material from becoming brittle after decades of contact with hot, oxygenated water.

- Pigment & UV Protection: Pigments are introduced via a Masterbatch. For pipes exposed to indirect sunlight, this must include UV stabilizers to prevent “chalking.” Crucially, for potable water, these must be Food Grade (NSF/WRAS certified) to ensure no heavy metals leach into the water supply.

- Opacity: ISO standards require pipes to be sufficiently opaque to block light, which is the only way to inhibit algae and bacterial growth within the system.

Global Benchmarks: The Importance of the Source

In the international market, the pedigree of the raw material is a primary indicator of quality. Industry professionals prioritize “Gold Standard” suppliers whose resins consistently exceed ISO requirements:

- Borealis (e.g., RA130E): Renowned for exceptional purity and thermal stability.

- LyondellBasell: Known for high-performance Hostalen grades.

- Hyosung: A major global provider of reliable PPR resins.

Procurement Insight: “Secondary” or recycled resins may pass initial 24-hour pressure tests, but they often lack the necessary Antioxidant package. Over 5 to 10 years, these inferior materials undergo de-polymerization, leading to sudden pipe bursts. To ensure a 50-year service life, always verify that your supplier uses 100% Virgin PPR Resin from a reputable global producer and request the Material Data Sheet (MDS) to confirm the Type 3 classification.

3. Technical Specifications: PPR Pipe SDR and PN Ratings

In the engineering and procurement of a PPR piping system, the “strength” and “hydraulic efficiency” of the network are not matters of subjective choice. They are governed by two interrelated metrics: SDR and PN.

For the professional, these figures are not just markings on a pipe—they are the blueprints for ensuring 50-year system integrity while optimizing material costs.

Understanding SDR: The Geometry of PPR Pipe DurabilityThe Standard Dimension Ratio (SDR) is the primary numerical value used to classify a pipe’s structural durability. Mathematically, it expresses the ratio of the pipe’s nominal outside diameter (D) to its minimum wall thickness (E) :SDR = D/E

The Inverse Correlation: In the context of PPR pipes, a lower SDR number indicates a thicker pipe wall relative to its diameter.

Mechanical Logic: As internal fluid pressure exerts “hoop stress” on the pipe walls, a thicker wall (lower SDR) provides a greater cross-sectional area to resist these forces. In high-rise applications, pipes with a lower SDR (such as SDR 6) are typically mandated for the lower floors where static head pressure is at its peak.

PN (Pressure Nominal) indicates the maximum pressure (in bar) that a PPR pipe can withstand during a continuous 50-year service life. It is critical to note that this rating is calibrated at a reference temperature of 20°C.

| SDR Rating | Typical PN Rating | Wall Profile | Primary Engineering Application |

|---|---|---|---|

| SDR 11 | PN 10 | Thin Wall | Cold water transport, low-pressure irrigation, and gravity-fed systems. |

| SDR 7.4 | PN 16 | Medium Wall | Standard residential and commercial cold/hot water distribution. |

| SDR 6 | PN 20 / 25 | Ultra-Thick Wall | High-temperature heating mains and high-pressure industrial lines. |

The “Ultimate” Insight: PPR Pipe Pressure-Temperature De-rating

Many designers assume that a PN 20 pipe can safely withstand 20 bar of pressure in any application. However, this rating only applies at a reference temperature of 20 °C.

Because PPR is a thermoplastic material, its strength decreases as operating temperature increases. As a result, the maximum allowable working pressure must be reduced at higher temperatures to maintain long-term reliability.

For example, an SDR 6 (PN 20) pipe rated at 20 bar at 20 °C can only operate at around 8.1 bar when used in a continuous 70 °C hot water system, in accordance with ISO 15874 design principles.

Hydraulic Efficiency and the “Over-Engineering” Trap

In professional plumbing system design and procurement, structural safety must be balanced with long-term hydraulic performance and operational efficiency. Over-specifying pipe pressure classes does not necessarily improve system reliability and can, in some cases, increase overall lifecycle costs.

- Head Loss and Pumping Costs:Selecting an unnecessarily thick-walled pipe—such as using SDR 6 where SDR 7.4 would meet the actual pressure requirements—reduces the internal diameter of the pipe. A smaller internal diameter increases fluid velocity and friction losses, resulting in higher head loss. Over the service life of the system, this leads to increased pumping energy demand and higher operating expenditure (OPEX).

- Material Economy (CAPEX): Compared with higher SDR classes such as SDR 11, SDR 6 pipes contain significantly more material per linear meter. In large-scale projects, accurately matching SDR selection to different pressure zones within the system can reduce material-related capital expenditure (CAPEX) by up to 15–20%, while still maintaining compliance with pressure and safety requirements.

- Thermal Expansion Stress: Thicker-walled pipes exhibit higher axial stiffness and can develop greater internal stresses during thermal expansion when pipe movement is restrained. In long hot-water distribution runs, SDR selection directly influences the design of expansion loops, fixed points, and anchoring systems.

💡 Note: The technical data, pressure de-rating figures, and SDR/PN correlations provided in this section are based on general industry standards (such as ISO 15874 and DIN 8077/8078) and are intended for informational purposes only.

While these values represent typical performance characteristics of high-quality PP-R Type 3 resins, actual performance may vary depending on specific raw material formulations and manufacturing tolerances.

Always consult the official Technical Data Sheet (TDS) from your specific supplier and verify calculations with a qualified MEP engineer before finalizing project specifications.

4. PPR Pipe Installation: The System Integration and Jointing Standards

The integrity of a PPR piping system depends as much on the quality of the installation as it does on the raw material.

Unlike traditional plumbing—which relies on mechanical threads or chemical glues—the PPR pipe installation process creates a permanent, leak-proof bond through molecular integration.

This chapter outlines the standards for creating a homogenous network.

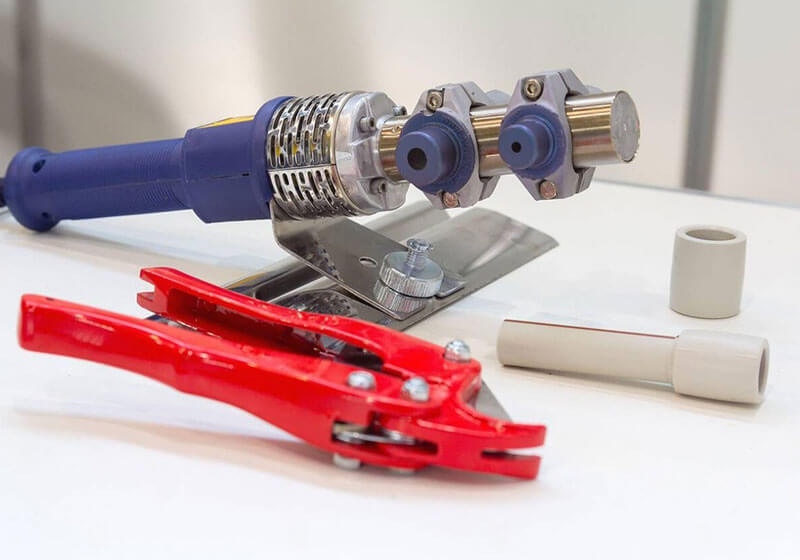

The Core Installation Method: Thermal Socket Fusion

The primary method for installing PPR pipes is Socket Fusion. This is not a mere “connection” but a process of molecular interdiffusion. When the pipe and fitting are heated to the crystalline melting point—precisely 260°C (±10°C)—the polymer chains become mobile.

- Molecular Bonding: As the pipe is inserted into the fitting, the molten surfaces merge. Upon cooling, the polymer chains from both components re-crystallize together.

- The Result: The interface disappears, resulting in a joint that is chemically and mechanically identical to the pipe wall itself.

Why This Installation System is Superior

For engineers and project managers, the PPR installation system offers several strategic advantages over legacy methods:

- Structural Continuity: In metallic or PVC systems, the joint is usually the “weakest link.” In a PPR installation, the joint is often stronger than the pipe itself because the fusion zone provides a double-layered wall thickness.

- Expansion Harmony: Since the joint and pipe are the same material, they share the exact same Coefficient of Linear Thermal Expansion (CLTE). They expand and contract in unison, preventing the fatigue leaks common in systems that mix plastic pipes with metal fittings.

- Hydraulic Smoothness: A correct installation ensures a seamless internal bore. This eliminates turbulence and prevents “stagnation zones” where bacteria (like Legionella) or mineral deposits might otherwise accumulate.

Technical Standards for a Successful Installation

To achieve the 50-year design life, the installation must follow the “Golden Rules” of the trade. Supervisors should monitor these three critical variables:

- Temperature Precision: The welding tool must maintain a constant 260°C. High-quality electronic thermostats are required; a 20-degree variance can lead to “cold joints” (insufficient bond) or polymer degradation.

- The “No-Turn” Rule: During the joining phase, the pipe must be pushed into the fitting socket linearly without rotation. Rotating the pipe disrupts the alignment of the molten polymer chains, creating internal shear planes that weaken the bond.

- The Visual Inspection (Double Bead): A perfect installation is characterized by a uniform “double bead” of molten material at the mouth of the fitting. This confirms that the correct amount of material was displaced and interwoven.

Environmental Factors in PPR Pipe Installation

Professional installation also requires accounting for the job site environment:

- Temperature Compensation: At ambient temperatures below 5°C, the heating time may need to be slightly extended (by roughly 50%) to compensate for the faster cooling rate of the molten plastic.

- Surface Purity: The presence of dust, oil, or water on the fusion surface acts as a contaminant. A “Golden Rule” is that all fusion surfaces must be clean, dry, and oil-free prior to heating.

- Procurement & Site Insight: The reliability of this installation system is the primary reason PPR is specified for concealed installations (behind walls or under floors). When properly installed and pressure-tested, the statistical probability of a joint failure is near zero, making it the safest choice for high-end infrastructure.

5. Key Benefits and Diverse Applications of PPR Pipe

The global shift toward PPR piping systems is driven by a unique combination of material longevity and installation security. By understanding the core benefits, engineers can better apply the system across residential, commercial, and industrial sectors.

Key Benefits of PPR Piping Systems

Corrosion and Chemical Resistance: PPR pipes are highly resistant to chemical reactions. Unlike metal pipes, they do not rust or react with acids, alkalis, or salts found in water. This ensures long-term water quality and eliminates the risk of “pitting” or pipe wall thinning over time.

Decades of Service Life: Designed for durability, PPR systems can last over 50 years under standard operating conditions. The heat-fused joints create a “one-body” system, significantly reducing leak points compared to mechanical or threaded systems.

Hydraulic Efficiency: The smooth inner surface minimizes friction, allowing for efficient laminar flow. This maintains consistent water pressure and prevents the buildup of lime-scale or sediment—a common failure in older galvanized steel pipes.

Thermal and Pressure Versatility: PPR systems handle a wide temperature range (typically 0°C to 95°C). Its high thermal insulation also reduces heat loss in hot water pipes and prevents condensation in chilled water lines.

Hygienic Integrity: As a food-grade material, PPR does not leach chemicals, heavy metals, or “plastic” odors into the water. Its smooth surface also inhibits bacterial growth, making it a “biologically safe” choice for drinking water.

Common Applications of PPR Pipe Systems

Potable Water Networks: PPR is the global standard for hot and cold drinking water due to its chemical inertness. Unlike metal pipes, it does not rust or leach heavy metals, ensuring water remains as pure at the tap as it was at the source. Its smooth internal surface prevents the mineral scaling and biofilm growth that often restrict flow in legacy systems. Because the heat-fused joints are leak-proof, it is the preferred choice for concealed installations in high-end residential and commercial developments.

HVAC and Climate Control: In large-scale climate control, PPR serves as the building’s “arteries.” For central heating, thick-walled SDR 6 pipes manage high-pressure, high-temperature distribution with ease. In chilled water systems for air conditioning, PPR’s low thermal conductivity naturally resists condensation (“pipe sweating”), protecting building structures from moisture damage while reducing the energy loss associated with metallic alternatives.

Industrial and Compressed Air Infrastructure: PPR is an industrial “workhorse” capable of transporting process water and non-aggressive chemicals that would corrode metal. It is particularly valued in compressed air systems; its rust-free nature ensures that sensitive pneumatic machinery is never damaged by pipe debris. The system’s ability to absorb vibration and handle pressure pulses makes it a safer, more durable option for modern factory floors.

Sustainable Heating Solutions: As green energy adoption rises, PPR provides the structural backbone for solar and radiant heating. It acts as the primary bridge between roof-mounted solar collectors and indoor storage. In underfloor heating, while flexible pipes like PE-RT are used for the floor loops, rigid PPR pipe is utilized for the main distribution manifolds and supply lines, ensuring a stable, pressure-balanced system that lasts for decades.

6. الخاتمة

The shift toward PPR piping systems is more than a trend; it is a fundamental upgrade in how we approach the longevity and safety of modern infrastructure.

From the molecular stability discussed in our opening chapters to the practical excellence of thermal fusion installation, every element of the PPR system is engineered for zero-failure performance. As building requirements become more stringent, the reliability and efficiency of PPR remain the definitive answer for professionals who refuse to compromise on quality.

At Ctube, we are dedicated to advancing the future of plastic piping through relentless research and manufacturing excellence. Understanding that our global clients require more than just basic components, we have expanded our portfolio to include a premium-grade PPR piping series designed for the most demanding environments.

To meet the diversified needs of modern projects, Ctube’s PPR solutions focus on high-molecular-weight resins and strict SDR compliance, ensuring that our products provide the structural integrity and chemical purity your projects deserve. We continue to innovate so that our partners can build faster, safer, and more sustainably.

Thank you for reading this guide. We hope these insights provide a valuable foundation for your future engineering and procurement decisions. If you have specific project requirements, we invite you to contact us.

الأسئلة الشائعة

Q1: PPR, PE-RT, and PEX—How do these three materials work together in a system?

Think of these three as a “System Family” where each plays a specific role based on its physical properties:

- PPR (The Structural Anchor): Because it is rigid and strong, PPR is the ideal choice for main supply lines and vertical risers that must stay straight and support their own weight.

- PE-RT & PEX (The Flexible Loopers): Because these materials are soft and come in long, continuous coils, they are used for underfloor heating loops or snaking through walls where you want to avoid joints.

- The Workflow: In a modern building, you typically use PPR to bring water from the boiler to the room, then transition to PE-RT or PEX to distribute that water within the space. They are not competitors; they are partners in creating a leak-proof network.

Q2: Since both are flexible, what is the actual difference between PE-RT and PEX?

While they look similar, their molecular chemistry sets them apart:

- PEX (Cross-linked Polyethylene): It is “cross-linked” to handle heat, making it extremely tough but impossible to melt. This means PEX relies entirely on mechanical fittings (crimping). If a PEX pipe is damaged, you must use a mechanical coupling to fix it.

- PE-RT (Raised Temperature Polyethylene): It achieves heat resistance through its unique molecular chain design rather than cross-linking. Crucially, PE-RT is a thermoplastic, meaning it can be heat-fused (welded) just like PPR. This makes it easier to repair, fully recyclable, and often more cost-effective.

Q3: Does the color of the PPR pipe (Green, White, Grey) indicate its quality?

No. Color is simply a pigment added for branding. The only “color” feature that matters technically is Opacity.

A high-quality pipe must be opaque to block light; if a pipe is translucent, it may allow algae to grow inside the system over time.

Q4: How do I know if the PPR pipe I bought is “High Quality”?

Beyond looking at certificates, you can perform three quick field checks:

- Opacity: Hold a flashlight against the pipe; if you can see light through the wall, the pipe is low quality and will allow algae growth.

- Smell: When heating the pipe for fusion, there should be no pungent or toxic odor—only a faint wax smell.

- Surface: The inner and outer walls should be perfectly smooth. Any “graininess” or bubbles indicate poor-quality raw material or improper extrusion.

Q5: Can I use PPR for industrial chemical transport?

PPR has excellent resistance to a wide range of chemicals, including many acids, bases, and aqueous solutions.

However, it is not universal. It can be sensitive to strong oxidizing agents and certain hydrocarbons (like gasoline or thinners).

Always consult the manufacturer before specifying PPR for industrial process lines to ensure compatibility with your specific fluid.

Q6: Is it necessary to insulate PPR pipes if they are used for hot water?

While PPR has low thermal conductivity, which is much better than copper, insulation is still recommended for long hot water runs. This isn’t just to prevent heat loss, but to ensure that the water reaches the furthest tap at the desired temperature.

For chilled water loops, insulation is essential to prevent any risk of surface condensation in high-humidity environments.