1. Introducción

En los sistemas eléctricos subterráneos, los conductos desempeñan un papel fundamental en la protección de los cables contra la humedad, la corrosión, los daños físicos y las condiciones cambiantes del suelo.

Para fabricar conductos subterráneos se utiliza una amplia variedad de materiales, incluidos metal, fibra de vidrio y, más comúnmente, PVC rígido debido a su resistencia, flexibilidad, rentabilidad y resistencia al estrés ambiental.

Dentro de la categoría de conductos rígidos de PVC, existen varios tipos diseñados para cumplir con diferentes profundidades de entierro, capacidades de carga y requisitos del proyecto.

Estos incluyen las series EB (enterramiento encapsulado) como EB20 y EB35, las series DB (enterramiento directo) como DB2, DB60, DB100, DB120 y los conocidos conductos con clasificación Schedule como SCH 40 y SCH 80.

Cada tipo ofrece beneficios únicos según el entorno de instalación.

Entre ellos, el conducto DB2 se destaca como una solución ampliamente utilizada para el cableado eléctrico subterráneo, que combina facilidad de instalación, alta resistencia al impacto y cumplimiento de las estrictas normas de seguridad canadienses.

Entonces, ¿qué es exactamente? Conducto DB2, ¿Y cómo se compara con otras opciones del mercado? Esta guía podría darte la respuesta.

Si es un contratista, ingeniero o gerente de proyectos que busca una solución de conductos subterráneos confiable y asequible, especialmente para proyectos residenciales o de servicios públicos a gran escala donde la eficiencia es clave, definitivamente vale la pena considerar el conducto DB2.

2. ¿Qué es DB2 Conduit? Definición y material

El conducto DB2 es un tipo de conducto rígido de cloruro de polivinilo (PVC) diseñado específicamente para enterramiento directo en instalaciones eléctricas subterráneas.

El término “DB” significa “Entierro directo”.” destacando su idoneidad para ser instalado directamente en el suelo sin necesidad de encofrado de hormigón.

El “2” en DB2 Se utiliza para diferenciar este tipo específico de conducto de otras opciones de entierro directo.

El conducto DB2 generalmente cumple con la norma CSA C22.2 No. 211.1, el estándar canadiense para sistemas de conductos no metálicos, lo que garantiza que cumple con los requisitos de resistencia mecánica, resistencia al impacto y durabilidad ambiental.

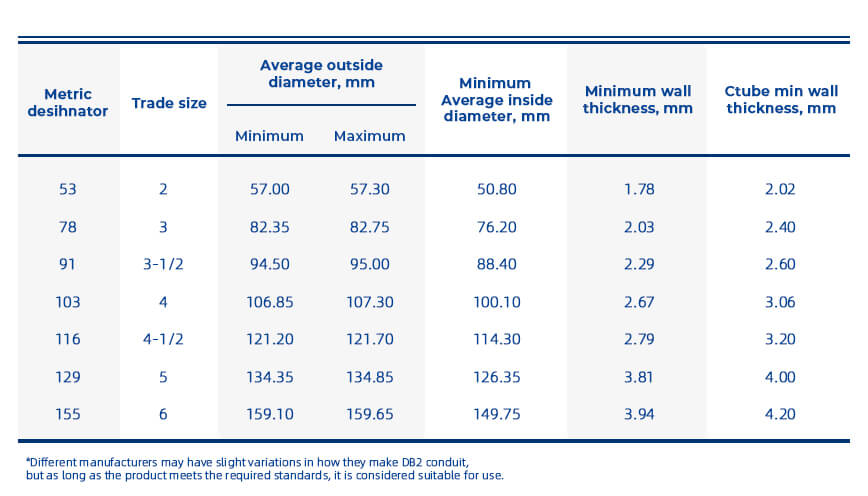

Por lo general, está disponible en tamaños que van desde 2″ a 6″ de diámetro, con longitudes estándar de 10 pies o 20 pies.

Si bien el gris es el color estándar para los conductos, también hay opciones como rojo, naranja y otros colores personalizados para satisfacer diversas necesidades de aplicación.

El conducto DB2 es fácil de instalar y generalmente se une utilizando cemento solvente para lograr un sellado seguro y hermético.

Es compatible con accesorios subterráneos de PVC estándar, como codos, curvas de barrido, acoplamientos y adaptadores, que permiten cambios de dirección, conexiones y transiciones a cajas eléctricas.

Muchos conductos DB2 también vienen con extremos de campana para simplificar la instalación.

3. Características principales de DB2 Conduit

Una de las características destacadas del conducto DB2 es su construcción ligera. Fabricado en PVC rígido, el conducto DB2 es significativamente más ligero que las alternativas metálicas, lo que facilita su manipulación, transporte e instalación. Esto no solo reduce los costos de mano de obra, sino que también agiliza el proceso de instalación.

El conducto DB2 ofrece una solución muy rentable para instalaciones eléctricas subterráneas. Su precio suele ser inferior al de los conductos metálicos y, al no requerir tratamientos adicionales como protección contra la corrosión, reduce tanto los costes iniciales de material como los gastos de mantenimiento a largo plazo.

Según la norma, las muestras de conductos deben soportar una energía de impacto de 61 julios a 23 °C y 34 julios a -18 °C, utilizando el procedimiento de prueba del Método A.

De diez muestras analizadas a cada temperatura, al menos nueve no deben mostrar grietas ni rajaduras visibles, ni en las superficies interiores ni en las exteriores, cuando se examinan con visión normal o corregida a la normalidad.

Este requisito de rendimiento demuestra la capacidad del conducto para soportar un estrés mecánico sustancial tanto en condiciones climáticas típicas como frías sin comprometer la integridad estructural.

El conducto DB2 está diseñado específicamente para aplicaciones subterráneas, donde la carga mecánica a largo plazo causada por la presión del suelo es un factor crítico.

Según la norma CSA C22.2 n.° 211.0, el conducto DB2 debe presentar una deformación limitada bajo carga. En pruebas a 23 ± 2 °C, la reducción promedio del diámetro bajo la carga aplicada no debe superar los 101 TP³T y debe recuperarse a un valor de 51 TP³T de su diámetro original una vez retirada la carga.

Los entornos subterráneos a menudo exponen los sistemas de conductos a la humedad, a los productos químicos del suelo y a posibles contaminantes.

El conducto DB2 debe pasar la prueba de resistencia química definida en CSA B137.0 (Definiciones, requisitos generales y métodos de prueba para tuberías de presión termoplásticas), que no muestre un cambio de masa mayor a 2% después de 7 días de inmersión en soluciones químicas designadas.

Además, su resistencia a la tracción debe permanecer dentro de 15% del valor original después de la exposición química.

Estos requisitos confirman que el conducto DB2 resiste la degradación, la hinchazón o la pérdida de resistencia cuando está en contacto con agua, sales o ácidos suaves, lo que garantiza su longevidad en instalaciones difíciles.

El conducto DB2 está diseñado con un cuidadoso equilibrio entre rigidez estructural y flexibilidad. Según la norma ASTM D2412 (Método de prueba estándar para la determinación de las características de carga externa de tuberías de plástico mediante carga de placas paralelas), debe alcanzar una rigidez mínima de 300 kPa con una deflexión de 5%, lo que garantiza una resistencia suficiente a la deformación causada por la presión del suelo o del relleno.

Al mismo tiempo, su pared más delgada (en comparación con el PVC cédula 40 u 80) facilita su manejo y doblado durante la instalación. Este equilibrio reduce el tiempo de instalación y los costos de mano de obra, a la vez que mantiene la protección mecánica necesaria para los sistemas eléctricos enterrados.

El conducto DB2 está diseñado para cumplir con los requisitos esenciales de seguridad contra incendios. Una de sus características clave es su resistencia al fuego: no favorece la combustión y se autoextingue una vez que se elimina la fuente de la llama. Esta propiedad ayuda a limitar la propagación del fuego y contribuye a la seguridad general del sistema.

Los fabricantes suelen incorporar aditivos específicos en la formulación del PVC para lograr estas características ignífugas. Por ejemplo, en Ctube, formulamos cuidadosamente nuestro conducto DB2 con compuestos de alta calidad y probados para garantizar una resistencia al fuego constante en todos los lotes. El resultado es un conducto que cumple con las normas de seguridad pertinentes, a la vez que es ligero, duradero y fácil de instalar.

4. Conducto DB2: Comparación con otros conductos (por ejemplo, conducto SCH 40)

Ahora que hemos explorado las ventajas clave del conducto DB2, veamos más de cerca cómo se compara con otras opciones de conductos comúnmente utilizadas.

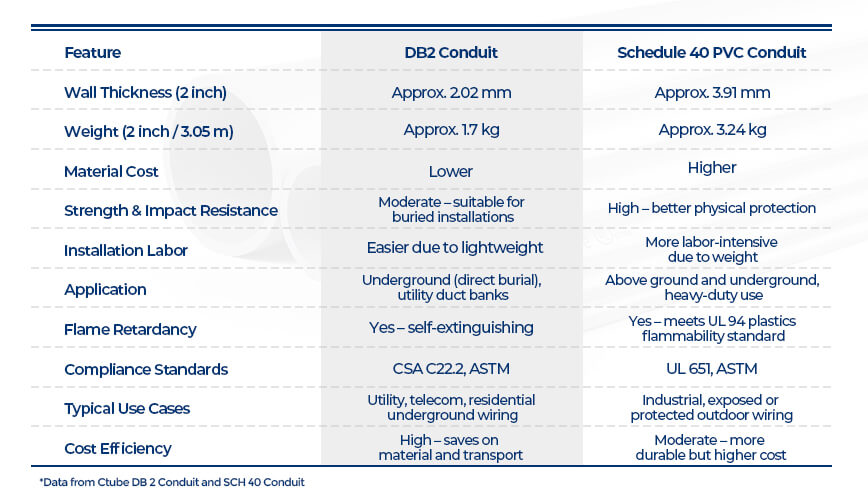

Para ayudar a ilustrar sus beneficios, primero compararemos DB2 con otro conducto de PVC ampliamente utilizado: Schedule 40.

Al comprender cómo se compara el DB2 con el PVC Schedule 40, puede evaluar mejor qué opción es la más adecuada para sus necesidades de instalación eléctrica subterránea.

Los datos de este ejemplo se basan en productos Ctube.

Una de las diferencias más notables entre el conducto DB2 y el conducto Schedule 40 es el peso.

Por ejemplo, el conducto de PVC Schedule 40 de 2 pulgadas de Ctube pesa aproximadamente 3,24 kilogramos por cada 3,05 metros de longitud, mientras que el conducto DB2 de 2 pulgadas de Ctube pesa solo 1,7 kilogramos para la misma longitud.

Otra diferencia notable entre los conductos Schedule 40 y DB2 radica en el espesor y la resistencia de sus paredes.

Para un conducto de 2 pulgadas de diámetro, el PVC Schedule 40 tiene un espesor de pared de 3,91 milímetros, mientras que el PVC DB2 tiene un espesor de pared más delgado de 2,02 milímetros.

La pared más gruesa del conducto Schedule 40 proporciona mayor durabilidad y resistencia al impacto que el conducto DB2.

Además de las diferencias en peso, grosor de pared y rendimiento, otro factor clave a considerar es el precio.

Dado que el conducto de PVC Schedule 40 ofrece una protección física y una resistencia superiores debido a su pared más gruesa, generalmente tiene un precio más alto en comparación con el conducto DB2.

Como resultado, los costos de transporte y manipulación de mano de obra también aumentan.

El conducto DB2 ofrece una opción más económica para instalaciones subterráneas sin comprometer el rendimiento esencial. El ahorro general en materiales, transporte e instalación convierte al conducto DB2 en una opción altamente competitiva para proyectos donde la eficiencia presupuestaria es una prioridad.

A diferencia de los conductos de metal, que pueden ser engorrosos y requerir equipos de elevación especiales para su manipulación, el conducto DB2 es lo suficientemente liviano para que los instaladores puedan trabajar con él manualmente, lo que puede contribuir a ahorrar costos generales de mano de obra.

El DB2 es mucho más liviano que el RMC, lo que hace que sea más fácil de manipular y más rápido de instalar sin herramientas de elevación especiales.

El conducto DB2 está fabricado con PVC rígido no metálico, lo que lo hace naturalmente resistente a la corrosión. Esta es una gran ventaja sobre los conductos metálicos, como el RMC, que pueden oxidarse y corroerse con el tiempo, especialmente al exponerse a la humedad o a condiciones climáticas adversas.

Otra diferencia significativa es el aislamiento eléctrico. El conducto DB2 está fabricado con PVC, un material no conductor, que proporciona aislamiento eléctrico integrado. Esto elimina la necesidad de pasos de conexión a tierra o unión independientes, esenciales al trabajar con conductos metálicos como el RMC.

En términos de costo, el conducto DB2 ofrece una clara ventaja sobre los conductos metálicos como el RMC. El DB2 es más económico tanto en costo de material como en instalación, ya que su diseño ligero reduce la necesidad de mano de obra o equipo especializado.

Los conductos metálicos, por otro lado, tienden a tener costos de material más altos y requieren una instalación más compleja.

Es importante reconocer que, si bien los conductos DB2 son más livianos y rentables, los conductos de metal pueden ser la mejor opción en entornos donde se requiere mayor resistencia y durabilidad.

5. Conclusión

En resumen, el conducto DB2 ofrece una excelente solución para instalaciones eléctricas subterráneas, proporcionando una opción confiable, rentable y eficiente para contratistas, ingenieros y gerentes de proyectos.

Con su diseño liviano, facilidad de manejo y rendimiento robusto, el conducto DB2 se destaca por su capacidad de cumplir con estándares rigurosos al tiempo que garantiza durabilidad a largo plazo y un mantenimiento mínimo.

En conclusión, la elección del conducto adecuado depende de diversos factores, como el presupuesto del proyecto, el entorno de aplicación y los requisitos específicos. Es fundamental sopesar las ventajas y limitaciones de cada opción para garantizar la mejor opción para las necesidades de su proyecto.

Tubo C es un fabricante de conductos y accesorios eléctricos de alta calidad con sede en China. Ofrecemos una amplia gama de conductos de PVC, incluyendo tipos rígidos como DB2, Cédula 40 y Cédula 80, así como opciones flexibles como Tubos Eléctricos No Metálicos (ENT).

Nuestra línea de productos también incluye soluciones especializadas como conductos solares de UPVC y conductos libres de halógenos y con baja emisión de humo, todos diseñados para cumplir con los estándares internacionales.

Ya sea que esté trabajando en instalaciones subterráneas o en proyectos a gran escala y sensibles a los costos, Ctube ofrece soluciones de conductos duraderas, compatibles con el código y personalizables para satisfacer sus necesidades de infraestructura eléctrica.

Gracias por leer. Agradecemos su tiempo e interés. ¡Le deseamos éxito en todos sus proyectos!