جدول المحتويات

تبديل1. المقدمة

If you’ve ever worked on a structured cabling project or explored the installation of fiber optics, Ethernet, or CCTV systems, you may have come across the term “communication conduit.”

Some people are already familiar with it, but it’s still unclear for many others. What exactly is a communication conduit? Is it just another type of electrical conduit? Is it the same as fiber conduit? And how do you choose the right one?

You’re not alone if you’re asking these questions. The term “communication conduit” can be confusing because it’s used across different technologies and environments.

In this post, we’ll focus on communication conduits and walk through the key concepts, conduit types, materials, standards, and selection strategies—step by step.

If you’re a project manager, contractor, or engineer, this article may be especially useful in helping you make informed decisions.

2. What Is a Communication Conduit?

A communication conduit is a type of protective tubing used to house and route low-voltage communication cables. These cables may include:

Fiber optic cables (for high-speed internet and data transmission)

Ethernet cables (Cat5e, Cat6, Cat6A for LAN networks)

Coaxial cables (for TV and CCTV)

Low-voltage signal cables (for alarms, intercoms, automation systems)

3. What Is Communication Conduit Used For?

The purpose of communication conduit is to:

Protect cables from mechanical damage, moisture, and UV radiation

Organize and simplify complex cabling layouts

Ensure code compliance for fire safety and building regulations

Support future upgrades by making cables accessible and easier to replace

While it shares similarities with electrical conduit, communication conduit is typically used for non-power applications, carrying signals rather than electrical current.

Think of it as the “highway” that keeps your structured cabling system organized, safe, and scalable.

4. Communication Conduit vs. Fiber Conduit: What’s the Difference?

As we mentioned above, one of the key functions of communication conduit is to protect fiber optic cables—and the conduit specifically designed for this purpose, known as fiber conduit, is actually a subset of the broader communication conduit category.

👉Simply speaking, fiber conduit is a specific subtype of communication conduit—designed to meet the unique requirements of fiber optic cables, which are more sensitive than copper-based cables.

5. What Are the Main Types of Communication Conduit?

When talking about types of communication conduits, it’s important to understand that there isn’t just one standard way to categorize them—instead, communication conduits can be grouped based on material, structure, installation environment, or application.

👀Let’s take a closer look at the four main classification dimensions.

Material → Structure → Cable Type → Application Environment

5.1 Communication Conduits Are Classified by Material to Suit Different Applications

When selecting a communication conduit, the material determines its mechanical properties, fire resistance, and environmental suitability. Common options include

PVC Communication Conduit—Lightweight and easy to install; commonly used indoors or in protected areas.

HDPE Conduit—Flexible and ideal for underground or directional boring applications.

LSZH Communication Conduit—Best suited for enclosed or high-safety environments like data centers.

Metal Conduit (rare for communication)—Used where enhanced security or shielding is required.

أنابيب الألياف الزجاجية—Strong, non-corrosive, and non-metallic. Suitable for harsh environments, including outdoor or industrial sites with high temperatures or chemical exposure.

5.2 Communication Conduits Can Be Rigid or Flexible Depending on Design Requirements

The structure of a communication conduit affects how and where it can be installed:

Rigid Communication Conduit—Provides strong physical protection; commonly used in commercial or riser applications.

Flexible Communication Conduit—Offers easier routing in confined or complex environments.

5.3 Communication Conduits Are Chosen Based on the Cable Type They Protect

The function of a communication conduit is directly tied to the type of signal or cable it houses:

Fiber Optic Cable Conduit—Engineered to safeguard sensitive fiber cables from bends, water, or crush damage.

Ethernet Conduit for Cat5e/Cat6—Maintains signal integrity in structured LAN networks.

Coaxial Communication Conduit—Supports CCTV and RF systems by protecting shielding-sensitive cables.

Hybrid Communication Conduit—Large conduits bundling multiple cable types for integrated telecom installations.

5.4 Communication Conduits Must Comply with Their Installation Environment and Code Requirements

Different environments demand different ratings for communication conduits:

Plenum-Rated Communication Conduit—Meets strict fire and smoke standards for air-handling spaces (e.g., UL 2024).

Riser-Rated Communication Conduit—Suitable for vertical installations between building floors.

Underground Communication Conduit—Moisture-resistant and crush-proof, typically HDPE or DB/EB-rated PVC.

Outdoor-Rated Communication Conduit—UV-stabilized and weather-resistant for exposed installations.

6. Key Considerations for Selecting a Communication Conduit

Now that we’ve explored the different classifications of communication conduit—let’s take a step further and look at how these classifications guide your selection process.

6.1 Type of Cable and Bandwidth Requirement

Different types of communication cables—like fiber optic, Cat6, coaxial, or twisted pair cables—have different physical and performance needs.

Fiber optic cables, for instance, require conduits with smooth interiors and wide enough diameters to avoid bending stress.

High-bandwidth applications often need more space and better EMI isolation.

6.2 Installation Environment

Is the conduit going indoors, outdoors, underground, or in plenum spaces?

Outdoor or underground installations need UV-resistant and waterproof conduits, such as PVC or HDPE.

6.3 Fire Resistance and EMI Protection

Some applications need enhanced fire resistance and shielding from electromagnetic interference (EMI).

Use metallic communication conduits or composite shielding layers in EMI-prone areas like data centers or industrial sites.

For fire-sensitive buildings, halogen-free or plenum-rated conduit is critical.

6.4 Space Planning and Future Scalability

Choose conduit sizes that allow for additional cables later on.

Modular conduit systems, junctions, and pull boxes support easier upgrades and replacements.

6.5 Compliance with Local and International Standards

When selecting a communication conduit, it’s important to follow local and international standards to ensure safety, compatibility, and long-term performance.

In the United States, key codes like the NEC and TIA standards regulate the use of conduits for fiber, coaxial, and other communication cables. Look for UL-listed options for safety assurance.

In Australia and New Zealand, AS/NZS 2053 and AS/CA S009:2013 provide clear rules for conduit type, color, and installation—especially in outdoor and underground settings.

Globally, standards like ISO/IEC 14763-2 and EN 50085 guide conduit use in structured cabling and ICT systems.

🌏Following these standards helps ensure your installation is safe, compliant, and built to last.

7. Understanding Color Coding and Compliance for Communication Conduits in Australia

Based on feedback we’ve collected from electricians, engineers, and contractors—along with references to key industry standards—we’ve found that in Australia and New Zealand, AS/NZS 2053 medium-duty white non metallic conduit is most commonly used for communication cabling, such as MD white PVC conduit with 750 N.

This choice is not only practical but also aligns with installation habits and compliance requirements across both countries.

When installing communication conduits—especially in environments like underground or outdoor systems—color and compliance are critical for safety and clarity.

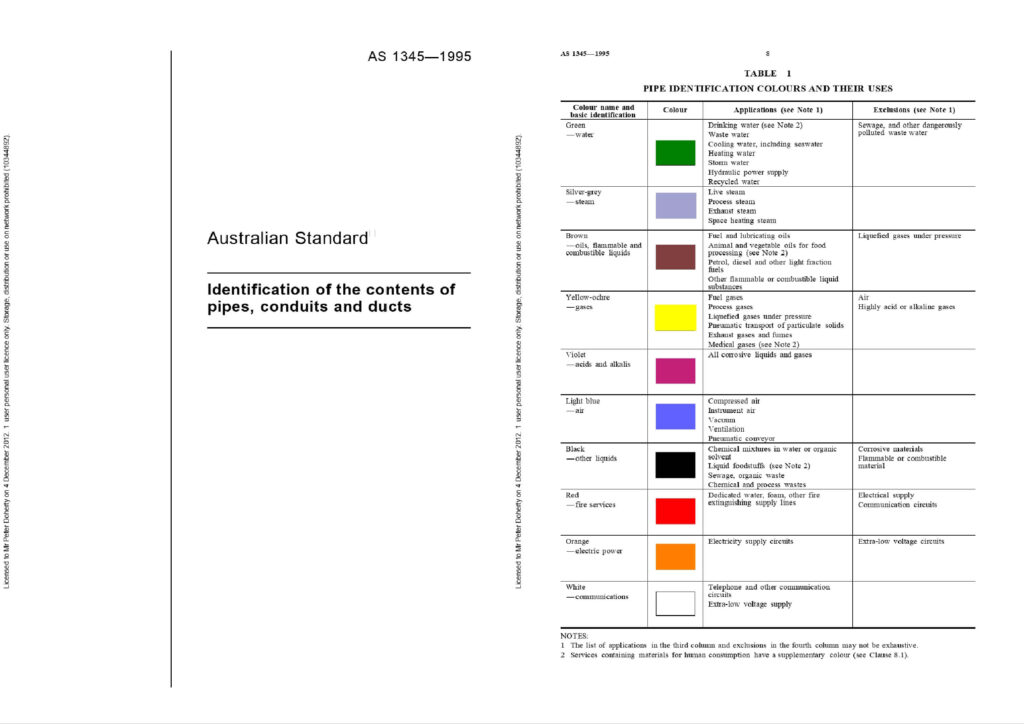

Australian standards like AS 1345:1995, AS/CA S008:2020 and AS/CA S009:2013 have provided clear guidelines for years.

We will introduce the content about communication among these standards one by one.

In Australia, conduit colors are defined under AS 1345:1995, and communication conduits must not use colors reserved for hazardous services.

According to AS/CA S008:2020, here are the requirements of communication conduit underground.

Underground plastic conduit used for communication must be either fully white, or have a durable white stripe that is part of the manufacturing process (not painted on afterward).

The conduit must be durable, moisture-resistant, and suitable for medium-duty use, whether rigid or flexible, threadable or not, and rated to IP66.

Underground conduits must be clearly and durably marked “COMMUNICATIONS” at regular intervals, without using the word “ELECTRICAL” to prevent confusion.

While in AS/CA S009:2013, there are more detailed requirements about communication conduit installation.

✅ Tip: Always choose colors that don’t appear in this list for communication conduits. The following table is the hazardous colors to avoid for communications cabling.

| لون | Meaning / Use |

| البرتقالي | AC mains power |

| Yellow | Fuel, toxic, or medical gases |

| Silver-grey | Steam |

| Brown | Flammable or combustible liquids |

| Violet | Acids and alkalis |

| Light Blue | Compressed air |

For indoor use, any non-hazardous color is allowed, but white is recommended to help avoid confusion.

As we mentioned above, outdoor communication conduits must be solid white or have a built-in white stripe, clearly marked “COMMUNICATIONS,” and cannot be repainted from other colors like orange to meet the standard.

For outdoor surface and aerial installations, communication cables must be UV-resistant or fully protected inside suitable conduits, following AS/CA S008 standards.

Underground communication conduits must avoid hazardous colors unless they are fully encased in concrete and marked white, sub-ducted in compliant IPX8-rated conduit, or used for fiber optic cables with proper hazardous light warnings.

When installed under roads or footpaths, cables must be buried in compliant conduit at least 450 mm deep or protected with labeled white warning tape placed at least 100 mm above the cable.

8. Understanding Color Coding and Compliance for Communication Conduits in USA

The NEC doesn’t have any specific rules about conduit colors, unlike Australia and New Zealand where there are clear requirements.

Currently, there doesn’t seem to be any official standard that strictly defines which colors must be used. Instead, contractors and engineers have developed their own practical color schemes to make it easier to identify different types of conduits.

For communication conduits, which are mainly covered under NEC Articles 770 and 800.

Here we provide some key points required from the standard.

Both NEC 770 and 800 emphasize that communication conduits and cables must be physically separated from electrical power lines. This helps prevent electromagnetic interference and keeps the communication signals clean.

Metal parts of communication systems, like conduits and cable shields, must be properly grounded to avoid electrical hazards and improve safety. This grounding ensures all metal parts share the same electrical potential, protecting equipment and people.

Communication conduits and cables should be installed neatly and logically.

Avoid sharp bends or complex routing that make future repairs or upgrades difficult. Supports and clamps should be placed at regular intervals to keep conduits stable and secure.

Filling conduits too full can cause overheating or damage to cables, so maintain proper fill limits. Especially for fiber optic cables (Article 770), protecting the cables inside inner ducts is important to prevent damage and ease future maintenance.

Fiber optic cables have stricter rules because they are sensitive to bending and mechanical stress. They require larger conduit diameters and gentle bends to avoid signal loss or cable damage.

Inner ducts are commonly used to protect fiber cables inside conduits. When pulling fiber cables, care must be taken not to stretch or pinch them, ensuring the system remains reliable over time.

Communication cables and conduits must meet fire safety standards. For example, unused cables should be removed to avoid fire hazards. Cables cannot be installed inside pipes that carry dust, gases, or loose materials because this could cause damage or safety issues.

In special environments like air handling spaces, cables must use fire-resistant or low-smoke materials to reduce risks during a fire.

9. الخاتمة

Choosing the right communication conduit is essential for keeping your wiring systems safe, organized, and future-ready. Whether you’re planning a home internet setup, a commercial security system, or a large-scale fiber optic installation, it’s important to follow key guidelines when selecting conduits. That means considering things like environment, conduit size, color coding, and compliance with local standards.

To support all of these needs, سي تيوب offers a full range of PVC communication conduits that meet U.S. و Australian standards. Our products are strong, lightweight, easy to install, and suitable for both indoor and outdoor use. Whether you need conduits for buried lines, wall installations, or data center cabling, Ctube provides safe and dependable solutions you can count on.

With the right conduit, your communication system will run better, last longer, and stay safer.

📘 If you’re interested in learning more about the electrical conduit requirements in the AS/NZS 2053 standard, check out our article Understanding the AS/NZS 2053 Standard: A Comprehensive Guide for Electrical Conduits.

🟠 If you’re curious about orange electrical conduit, don’t miss Everything You Should Know About Orange Electrical Conduit.

🎯 Want to learn more about electrical conduit, installation tips, and the latest industry updates?

📩 Follow Ctube on لينكدإن or other social media like فيسبوك أو Instagram أو يوتيوب, we regularly share helpful information about PVC conduit, fittings, and best practices for electrical projects — whether you’re a contractor, engineer, or just planning your next project.

📚 Read more helpful post from our blog pages to learn more about electrical conduit.

Thank you for reading. We hope this article has been helpful in guiding your conduit selection. If you have any questions or need further assistance, feel free to contact us. We wish you great success with your project!