جدول المحتويات

تبديل1. Introduction to Electrical Conduit Sizing

When planning any electrical installation—whether it’s for a home project or a large-scale commercial job—choosing the right electrical conduit size is one of the most important steps.

Choosing the right electrical conduit size is a bit like picking the right suitcase for a trip. If it’s too small, you can’t fit everything in—and if it’s too big, you’re just carrying extra weight for no good reason. The same idea applies to electrical conduit sizing.

Conduits aren’t just protective tubes—they’re the highways for your wires.

If a conduit is too tight, it can cause the wires to overheat, make it nearly impossible to pull new cables through, or even violate NEC rules (National Electrical Code Conduit Size) .

If it’s too large, you may be spending more money on material and labor than necessary.

If you are wondering what size conduit for 6/3 wire or 8 gauge wire. Or maybe you’re confusing about what size conduit for 200 amp service.

This guide maybe give you the answer, we’ll show you how to calculate, choose, and troubleshoot conduit sizing with examples, fill charts, NEC references, and real-world scenarios. Whether you’re a contractor, engineer, electrician, or someone tackling a DIY electrical project, this post may be helpful.

2. Understanding Conduit Sizes and Standards

Before we dive into conduit size charts and wire calculations, let’s take a step back to understand conduit sizes.

If you’ve ever bought a pair of shoes from another country, you’ve probably noticed the sizes don’t always match what you’re used to.

A US size 9 isn’t the same as a European size 43, even though they’re for the same foot. The same thing happens with electrical conduit sizes.

2.1 What Is a Conduit Trade Size?

Conduit sizes are usually given in something called a “trade size.” This is like the label size, not the exact measurement.

For example, a 1-inch conduit (trade size) doesn’t have an inner or outer diameter that measures exactly 1 inch. That’s because trade sizes are more of a standard naming system used in the industry to simplify things—not precise measurements.

2.2 Actual Diameter vs Trade Size

Think of it this way: if the trade size is the name of a pizza (“large”), the actual diameter is how big the pizza really is (like 12 inches). The name helps you order, but the exact size can still vary.

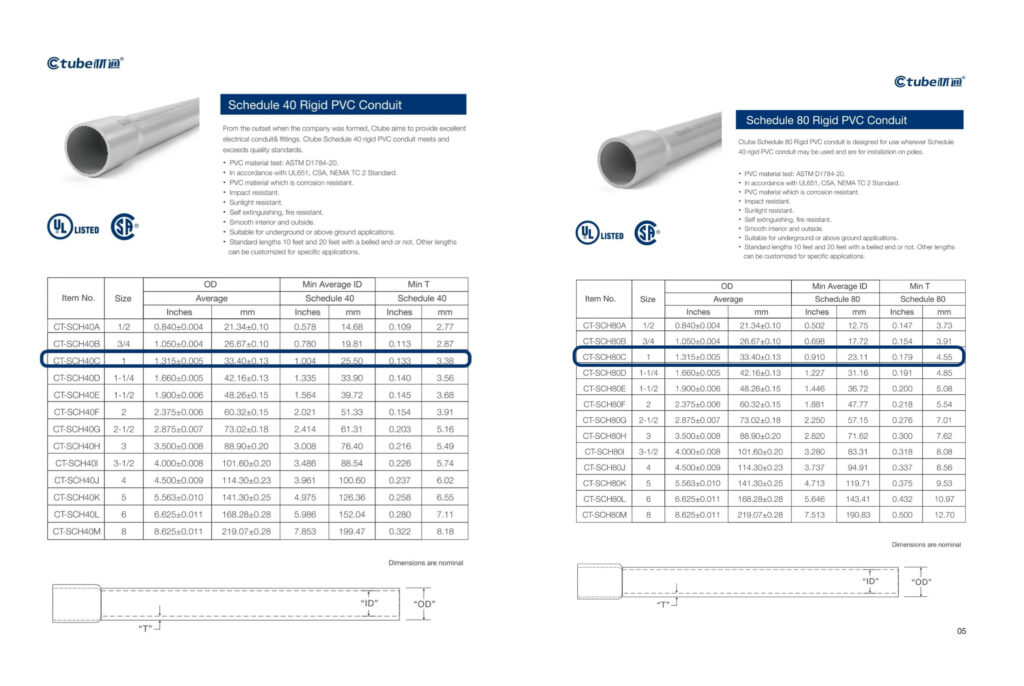

A 1-inch Schedule 40 PVC conduit of Ctube, for example, has an actual outer diameter of about 1.315 inches (33.4 mm).

A 1-inch metal conduit may have slightly different dimensions.

Different types of conduit (PVC, EMT, RMC, flexible metal, etc.) have different wall thicknesses, so even if they have the same trade size, the inner space (where the wires go) may differ.

2.3 Inches vs Millimeters: Regional Differences

Depending on where you are, conduit sizes might be listed in inches or millimeters:

In the U.S. and Canada, conduit sizes are mostly in inches (e.g., ½”, ¾”, 1″).

In many other parts of the world, especially Asia and Europe, metric sizes are common (e.g., 20mm, 25mm, 50mm).

3. Factors That Influence Electrical Conduit Size Selection

Now that we’ve covered the basics of conduit sizes, it’s time to look at what actually affects your choice.

Choosing the right conduit isn’t just about picking something that “looks big enough.” It depends on what’s going inside the conduit, where it’s being installed, and what it’s made of.

In this section, we’ll walk through the key factors you need to consider to ensure safe, code-compliant, and efficient conduit sizing.

3.1 Number and Type of Conductors

Think of electrical wires inside a conduit like people in an elevator. The more people you try to fit, the more crowded—and potentially unsafe—it becomes.

Similarly, the number and type of conductors (wires) inside a conduit directly impact how much space you need. The more conductors you plan to run, the bigger the conduit must be.

🧵 Solid vs. Stranded Wires: Stranded wires take up more space because of tiny air gaps between strands.

📏 Different wire gauges: Thicker wires need more room.

➡️ Detailed explained:

- Solid wire is a single, solid piece of metal. It’s compact and doesn’t take up much space.

- Stranded wire is made up of many thin strands twisted together. These strands create small air pockets, making the wire slightly thicker overall.

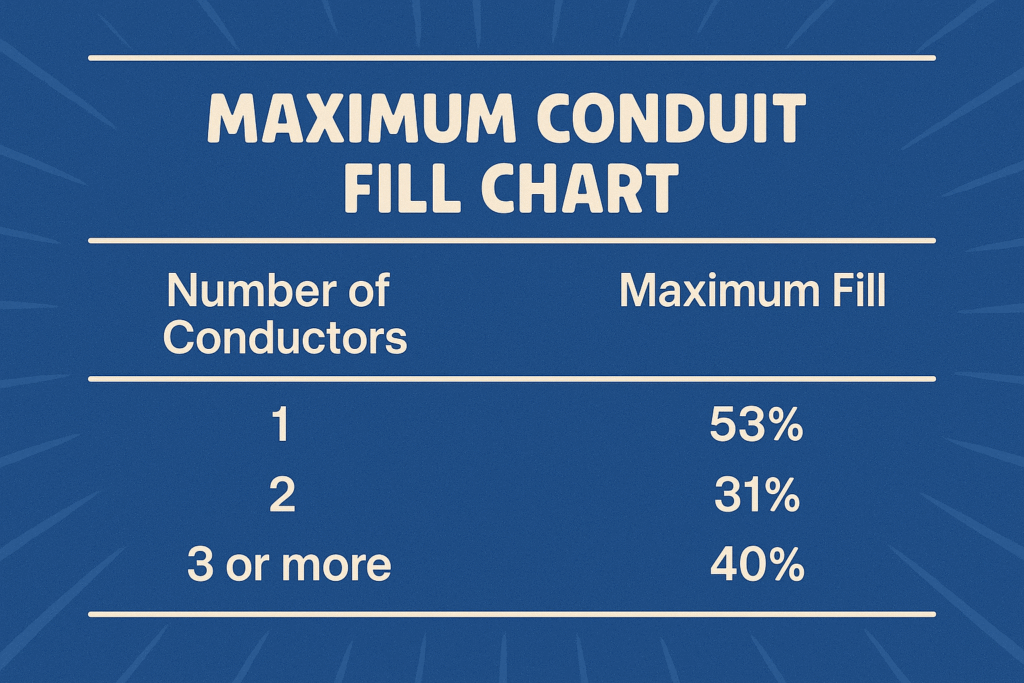

🧮 According to NEC Conduit Fill Table provide the Common Sizes and fill percentages (NEC Chapter 9Table 1)

- 1 wire: max 53% fill

- 2 wires: max 31% fill

- 3 or more wires: max 40% fill

3.2 Conductor Insulation and Voltage Rating

Not all wire insulation is created equal. Some types, like THHN or XHHW, are thinner, while others are thicker for higher voltage or better protection. The thicker the insulation, the more space each wire takes up.

Also, high-voltage wires may need more spacing between conductors, depending on code requirements and safety margins, which affects how large the conduit needs to be.

💡 Imagine each wire wearing a jacket—the thicker the jacket, the more room it takes up. And if that wire carries more voltage, the jacket needs to be thicker for safety.

3.3 Conduit Material and Conduit Types

PVC, metal, RTRC (fiberglass conduit), HDPE, —each type of conduit has different wall thicknesses, which means different interior diameters, even if the trade size is the same.

For example, same sizes PVC Schedule 40 has a larger inner space than Schedule 80 because the walls are thinner.

Rigid metal conduits (RMC) have thicker walls than EMT (Electrical Metallic Tubing), so you get less space inside even if the trade size is the same.

Same sizes PVC rigid conduit may be have a smaller inner space than Electrical Metallic Conduit (EMT) for its thinner wall thickness.

💡 It’s important to note that flexible conduit and rigid conduit have different designs. Even they are made from same material and labeled the same size, their actual internal space can be very different.

Rigid conduit is stiff and holds its shape, so the internal space is more consistent and predictable.

Flexible conduit, on the other hand, is bendable and made from a coiled material, which means it has tiny gaps and spaces between the coils.

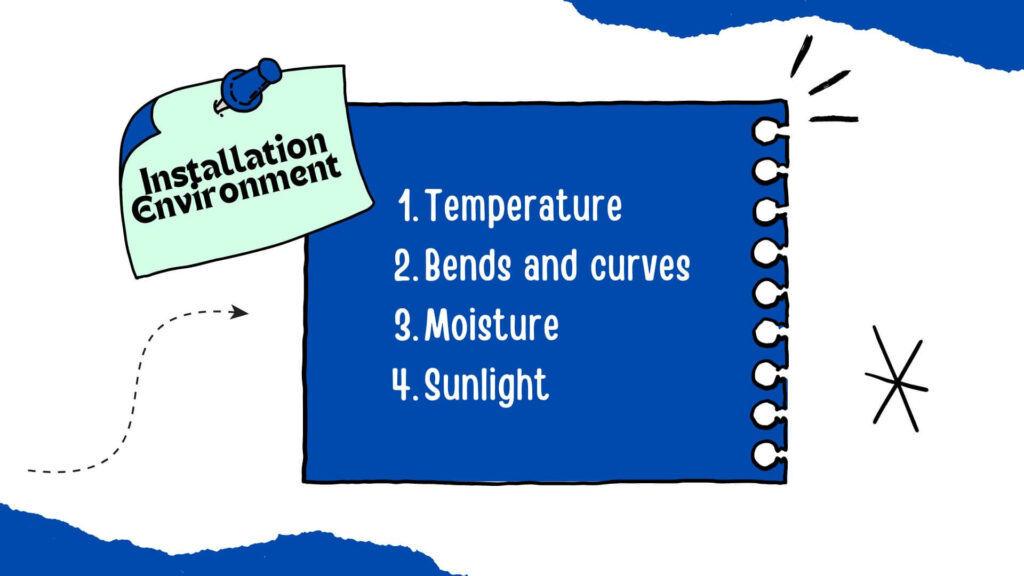

3.4 Installation Environment: Temperature, Bends, Moisture, and Sunlight Exposure

درجة حرارة: High-heat environments may require larger conduit for better ventilation.

Bends and curves: Wires are harder to pull through tight bends. A slightly larger conduit can make the pull smoother and avoid damage.

Moisture: In wet or underground areas, you may need sealed PVC or corrosion-resistant conduits.

Sunlight: UV exposure can weaken some plastics, so UV-rated materials may be needed.

The tougher the environment, the more likely you’ll need to upsize for safety and ease of maintenance.

4. How to Use Fill Chart and Calculate Electrical Conduit Size

Now that we’ve gone through the basic rules and charts, let’s look at how this all works in real life.

4.1 Guideline for Conduit Size Choosing and Fill Chart Usage

📌 You Can Use Different Methods Depending on the Situation

👉 Option 1: Use a Conduit Fill Chart

This is the easiest and fastest way. Just look up your wire type and size, and the chart tells you what size conduit will work. It’s perfect for common wire setups and quick jobs.

👉 Option 2: Do the Math Manually

This is a better choice when you have multiple wire sizes, special conditions, or need a very accurate result.

💡 If you decide to calculate it manually – whether you’re trying to figure out how many wires fit in a conduit, or which conduit size you need, we’ve got a simple method for you to calculate conduit fill.

💡 الخطوة 1: Figure out what kind of wires you’re using. That includes the wire size (called gauge), insulation type (like THHN), and how many wires you need to run.

💡 الخطوة 2: Know what kind of conduit you’re using. EMT, RMC, and PVC conduit all have different inner space, even if they’re the same “size.”

💡 الخطوة 3: Look up the wire’s size in NEC Table 5 to find the space (area) it takes up. Then, check NEC Chapter 9, Table 4 or Annex C to see how many of that wire can fit in your conduit type and size.

💡 الخطوة 4: Make sure you don’t go over the “fill limit.”(Table above) For most cases, you shouldn’t fill more than 40% of the space inside the conduit when running more than two wires.

📌Depending on your situation—like the number of wires, their type, and the conduit material—the exact steps might vary slightly.

For example, calculating fill for a single wire type is simpler than figuring out a mixed group of wires or planning a multi-voltage system.

Here we make some examples for you to better understand.

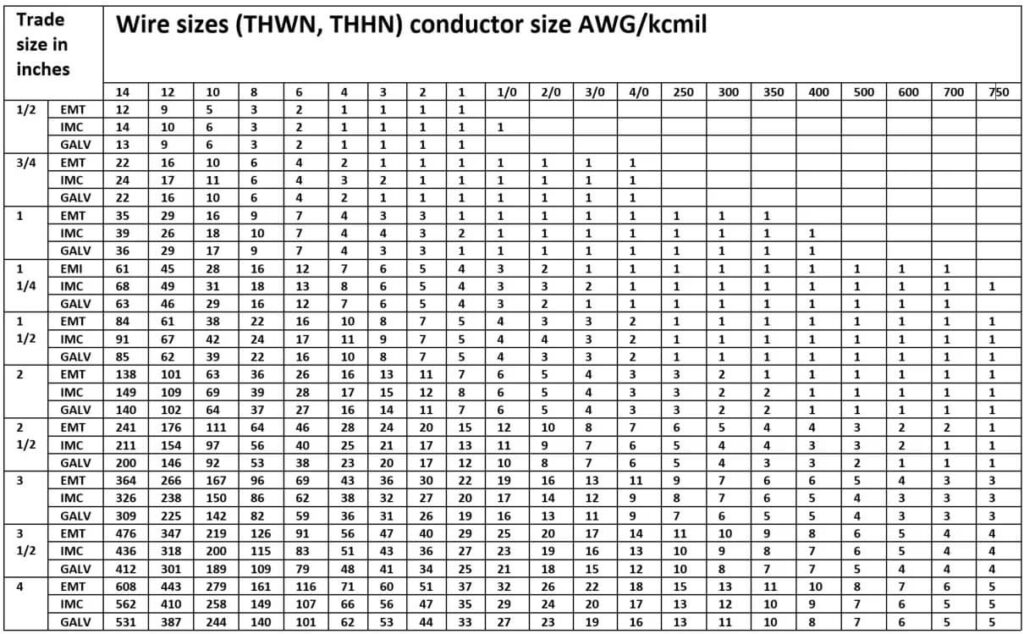

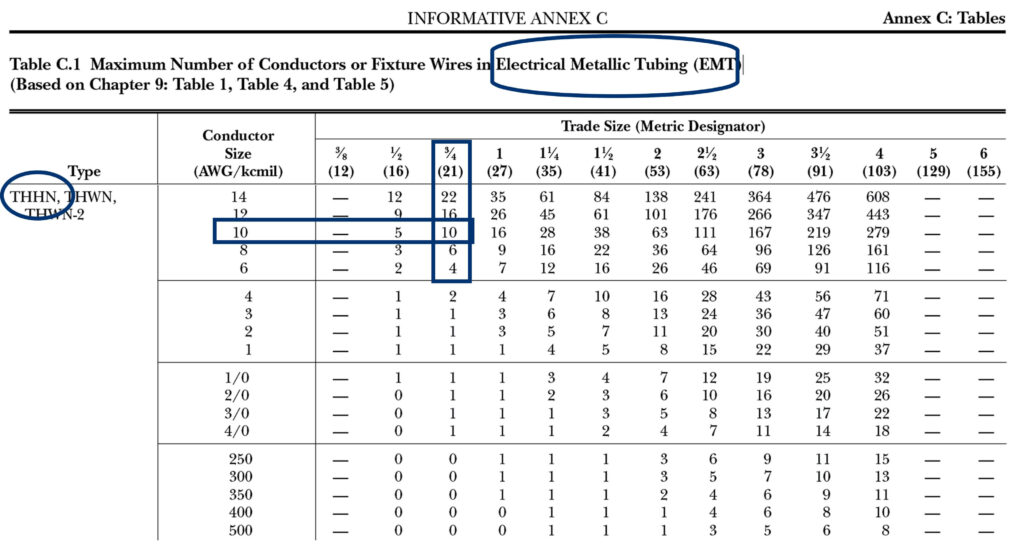

4.2 Example 1: How Many #10 THHN Wires in 3/4″ EMT? (single conductor)

🟢 First Method: Using a Conduit Fill Chart

This method is much quicker because it uses a chart that already does the math for you.

- You just need to:

- Look up the conduit size you’re using (e.g., 3/4″ EMT).

- Find the wire size (e.g., #10 THHN) in the chart.

- The chart will tell you exactly how many of those wires can fit in the conduit, based on its size.

It’s like using a shortcut—just find your size and wire type, and the chart gives you the answer instantly! No need for calculations.

🔴 Second Method: Manual Calculation Using Steps

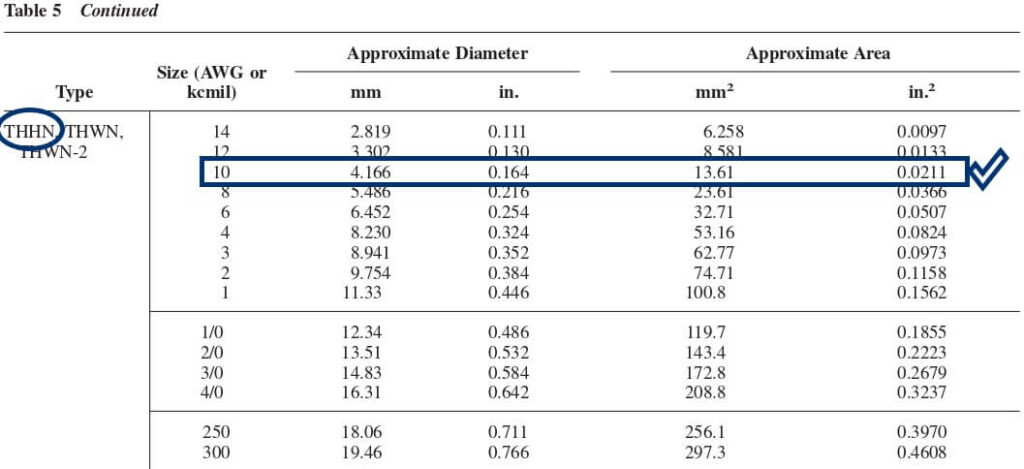

Step 1: Find the area of one #10 THHN wire

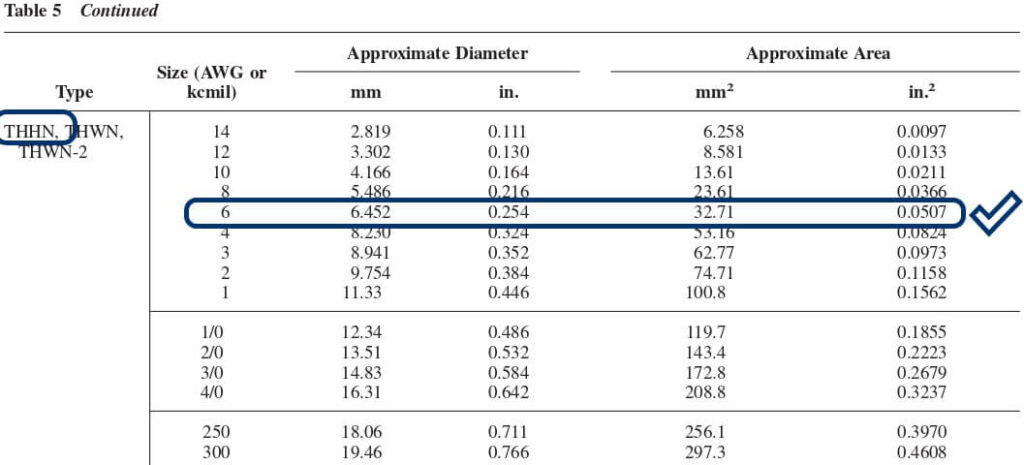

We’ll start by looking at NEC Table 5 to determine the area of a #10 THHN wire.

According to this table, the area for a single #10 THHN wire is 0.0211 square inches.

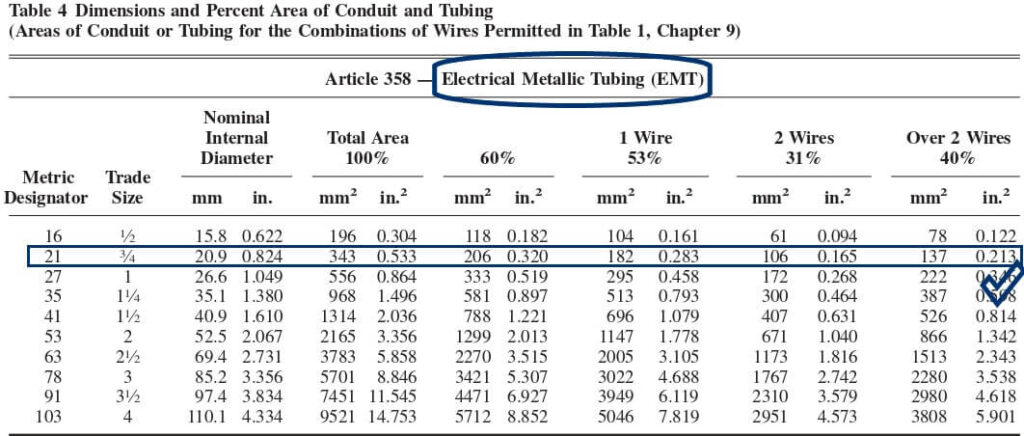

Step 2: Find the allowable fill area of ¾” EMT

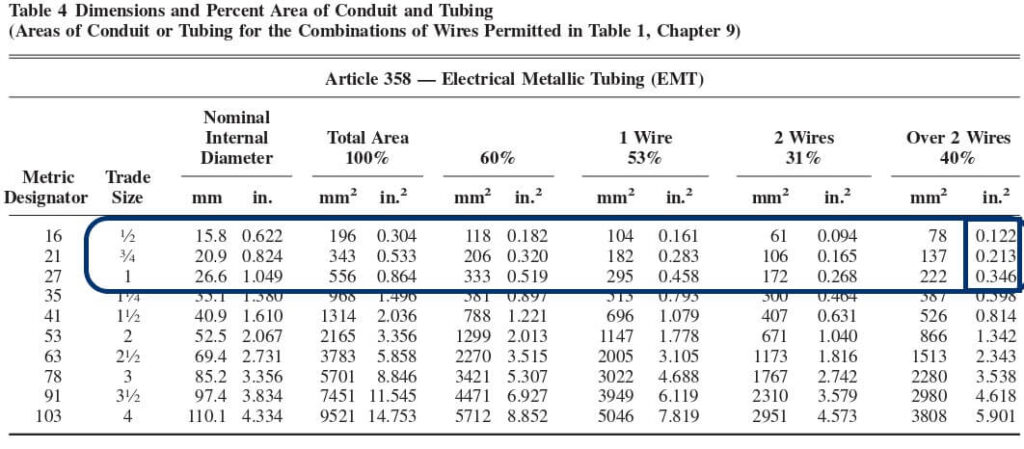

Next, we refer to the NEC Table 4 or Annex C for the fill capacity of a 3/4″ EMT conduit.

For 3/4″ EMT, the available space is 0.533 square inches.

40% fill limit = 0.533 × 0.40 = 0.2132 in²

Step 3: Divide to find how many wires fit

0.2132 ÷ 0.0211 ≈ 10.1

✅ That means you can safely run up to 10 #10 THHN wires in a ¾” EMT conduit when following the 40% fill rule.

🔍 You might see the wire type listed as THHN — that’s the insulation type, designed for high-temperature, dry-location installations, and commonly used inside conduit.

4.3 A More Complex Wire Run Introduction and Example

- In the example we just did, things were simple:

- We only used one type of wire: #10 THHN

- All wires were the same size and type

- There were no sharp bends or special installation needs

But in real life, things can get more complicated.

📌 Here’s why conduit fill can get tricky in real-world situations:

- You might have wires of different sizes or insulation types (like mixing THHN with XHHW)

- Some wires may carry different voltages, which means they may need to be separated

- Long wire runs may require extra space to reduce pulling tension

- If there are many bends or turns in the conduit, it may be harder to pull wires through, so a larger conduit might be needed

- Sometimes extra space is needed in the conduit for future expansion or easier maintenance

💡 That’s why in more complex projects, the calculation isn’t always so straightforward.

You may need to:

- Look at more than one NEC table (like Table 5, Table 8, and Annex C)

- Add up the space taken by each type of wire

- Or use an online conduit fill calculator to help make sure you stay within safe limits

👉 In short: the more types of wire or special conditions you have, the more careful your calculation needs to be.

Example 2: You’re running wires from a panel to a subpanel across a 60-foot distance in a commercial building.

- 3 wires of #6 THHN (for a 240V circuit)

- 1 #10 THHN wire for ground

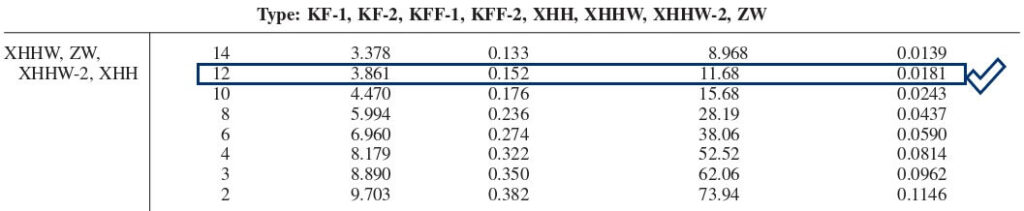

- 2 control wires: #12 XHHW

- The conduit will have two 90-degree bends

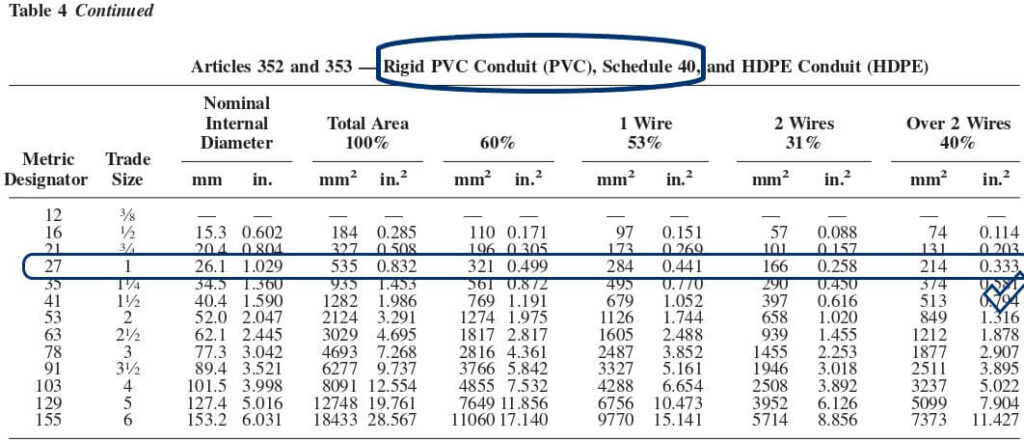

- You want to use 1 inch PVC conduit (Schedul 40)

📌 Step-by-Step

Step 1. List out your wires and their types

- 3x #6 THHN

- 1x #10 THHN

- 2x #12 XHHW

Each of these has a different size and insulation, so they take up different amounts of space.

Step 2. Look up each wire’s area (cross-section)

From NEC Table 5:

- #6 THHN ≈ 0.0507 in²

- #10 THHN ≈ 0.0211 in²

- #12 XHHW ≈ 0.0181 in²

Then, the XHHW one

Now, multiply each by the quantity:

- 3 x 0.0507 = 0.1521 in²

- 1 x 0.0211 = 0.0211 in²

- 2 x 0.0181 = 0.0362 in²

- Total wire area = 0.2245 in²

Step 3. Look up the allowable fill for 1 inch PVC conduit

From NEC: 40% fill for over 2 wires in 1 inch PVC conduit= 0.333 in²

4. Compare total wire area to conduit capacity

- Total wire area = 0.2245 in²

- 1″ PVC 40% fill limit = 0.333 in²

✅ You’re within limits — so it’s safe!

🔎 But there’s more to think about:

- Because you have two 90° bends, pulling the wires through will be harder.

- You might want to move up to a 1¼” conduit for easier installation.

- Or use sweeping bends instead of tight ones.

4.4 Example 3: What Size Conduit for 200 Amp Service (Using #3/0 THHN)

✅ 2 hots + 1 neutral + 1 ground = 4 wires for 200 Amp service.

🔴 Step 1: Find the wire fill area

According to NEC Chapter 9, Table 5, one #3/0 THHN wire takes up 0.2679 in² of space.

- 2 hot wires

- 1 neutral wire

- 1 ground wire (let’s say #4 THHN for now, which is 0.0824 in², according to the chart)

So the total area is:

- 3 × 0.2679 in² = 0.8037 in²

- 1 × 0.0824 in² = 0.0824 in²

- Total = 0.8858 in²

🔴 Step 2: Apply the conduit fill rule

You’re using more than two conductors, so according to NEC Table 1, the maximum fill is 40% of the conduit’s total space.

Now we need to find a conduit whose 40% fill is at least 0.8858 in².

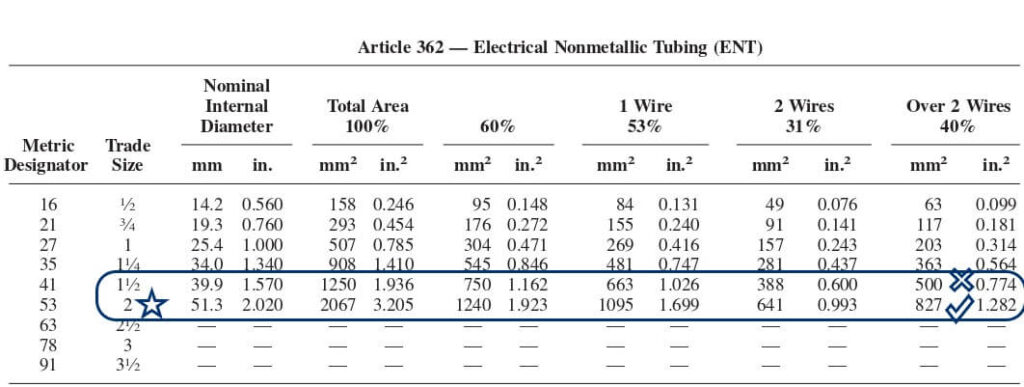

Let’s try 1,½ inch EMT: Total space: 0.774 in² at 40% fill

That’s not enough (since 0.794 < 0.8858)

Let’s try 2 inch EMT: Total space: 1.282 in² at 40% fill

That’s enough (since 1.282 > 0.8858)

✅ Answer: You can use 2 EMT conduit for this 200 amp setup with 3/0 THHN conductors.

💡 Explaination for you, if you have confusing abot 200 amps and 3/0 THHN.

✅ 1. 200 Amps Decides the Wire Size

We can’t just guess what wire to use—we have to choose the wire size based on how much current (amps) the system needs to carry.

Amp (short for ampere) measures the flow of electric current.

In this case, 200 amps is the amount of electricity your system needs to handle.

According to the NEC (National Electrical Code), a common wire size for carrying 200 amps safely is #3/0 (said “three-aught”) .

#3/0 is a heavy-gauge wire with enough capacity to carry 200 amps.

✅ 2. Wire Size Decides the Conduit Size

Once you know the wire type and size—like #3/0 THHN—you can look up its diameter and how much space (area) it takes up.

Add up the space all those wires take. Then, based on NEC conduit fill limits (usually no more than 40% full for more than two wires), we can figure out what size conduit you need.

✅ 3. Why 4 wires for 200 Amp service

Sometimes 3 wires can be used, but only in specific cases — usually when the conduit or cable is metallic and can act as the ground wire.

4.5 Example 3: What Size Conduit for 6/3 Wire (THHN)?

🧐 First, what does “6/3” mean?

The label 6/3 stands for a type of cable with:

- “6” = the wire size (AWG #6)

- “3” = three current-carrying conductors

- It also usually includes 1 bare ground wire, making it four wires total inside the cable.

- 👉 So you’re dealing with 4 total wires.

This setup is common for things like electric dryers, ovens, or subpanels in residential buildings.

📐 Step-by-Step: How to Choose the Right Conduit Size

✅ Step 1: Get the wire area

According to NEC Table 5, #6 THHN = 0.0507 in² per wire

Total for 4 wires: 0.0507 × 4 = 0.2028 in²

✅ Step 2: Apply NEC Fill Rule

For more than two wires in a conduit, the NEC fill limit is 40%.

✅ Step 3: Find the Right Size, here we Check EMT conduit fill chart

| EMT Size | 40% Fill (max) | Enough for 6/3 THHN? |

| ½” EMT | 0.122 in² | ❌ No (too small) |

| ¾” EMT | 0.213 in² | ✅ Yes (fits 0.2028 in²) |

| 1″ EMT | 0.346 in² | ✅ Yes, with extra space |

5. الخاتمة

In this post, we explored how to calculate conduit fill using both manual methods and conduit fill charts. Whether you’re checking how many wires fit into a conduit or deciding what size conduit you need, the key is understanding wire area, conduit capacity, and NEC fill limits.

We walked through several practical examples. These examples help illustrate the process, but they are simplified for learning purposes.

So while these examples provide a helpful starting point, always consult a licensed electrician or refer to your local electrical code when planning actual installations.

Using conduit fill charts can save time and improve accuracy, especially when dealing with multiple conductors or larger systems.

Ultimately, proper conduit sizing ensures safety, compliance, and reliable electrical performance.

6. More Information for You

💡 We introduce the definition about conductor, wire gauge (AWG) in this post very detailed and easy to understand, you can read as you want: Understanding PVC Conduit Fill Charts: A Comprehensive Guide (2025), you can learn more and help you better understand the relevant terms we mentioned in this post.

📝And If you want to learn conduit sizes measuring, you can check out this post كيفية قياس طول وقطر الأنابيب الكهربائية.

🔵 At Ctube, we specialize in manufacturing high-quality PVC conduit and fittings designed for safe and efficient electrical installations.

Our products meet international standards like UL, CSA and AS/NZS 2053, and we offer a wide range of conduit types and sizes—including rigid conduit like الجدول الزمني 40, الجدول 80, DB, EB, أنابيب كهربائية غير معدنية and special series like ألواح UPVC الشمسية و low smoke halogen-free options.

Whether you’re working on a residential, commercial, or industrial project, Ctube is here to support your needs with reliable, certified solutions and expert guidance.

Thank you for reading, and we hope this article was helpful. Wishing you success with your project!