جدول المحتويات

تبديل1. المقدمة

On job sites, we’ve seen black corrugated conduit and assumed it was PVC — only to find out later, it was actually HDPE. The confusion is understandable. Some HDPE conduit and PVC flexible conduit can come in similar corrugated exteriors.

But look closer, and you’ll see the differences run deeper. They’re made from different materials, follow different performance standards, and serve different roles in an electrical system.

In this article, we’ll clear up the confusion by comparing HDPE conduit and PVC conduit — not just by how they look, but by the differences behind them.

By understanding differences between PVC conduit and HDPE conduit, engineers, contractors, or procurement professionals will be better equipped to make the choice for their projects.

2. Structural Differences Between HDPE and PVC Conduit

While HDPE and PVC conduits can look similar at first glance — especially when both come in a corrugated form — the structural differences between them are significant and directly impact how they are used in the field.

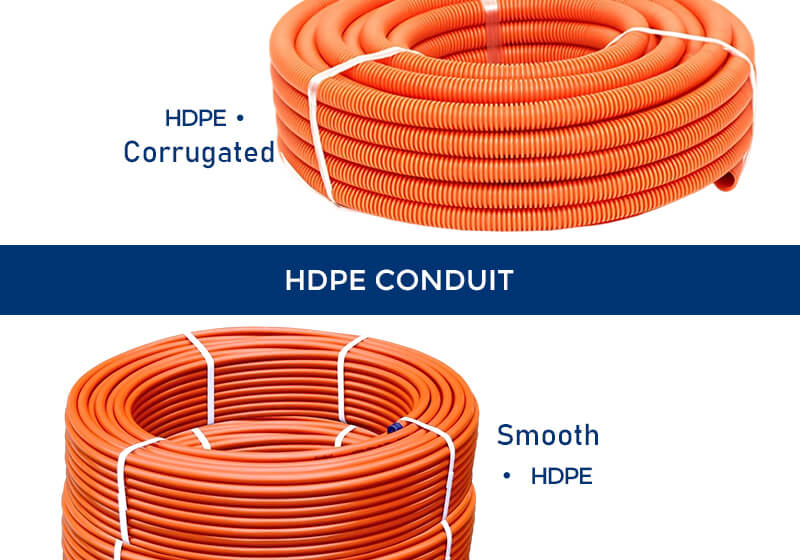

🧵 Exterior Surface: Smooth vs. Corrugated

HDPE conduit is available in both smooth-wall and corrugated designs.

The smooth-wall type is more common in telecom or utility installations where pulling cables over long distances requires minimal friction.

Corrugated HDPE, on the other hand, offers greater flexibility, especially for trenchless or curved installations.

PVC conduit also comes in different forms.

Rigid PVC conduit has a smooth and solid wall, offering structural strength and protection in exposed or embedded environments.

For flexible applications, ENT (Electrical Nonmetallic Tubing) is a type of corrugated PVC — often blue, gray or orange— used mainly for in-wall or slab installations in buildings.

📦 Coil Length and Delivery Form

HDPE conduit is typically supplied in long coils, sometimes hundreds of meters per roll, significantly reducing the need for joints and couplings in long runs.

PVC conduit, especially rigid types, is usually provided in standard straight lengths (e.g., 10 ft or 3 m), while ENT is often coiled in shorter sections suitable for indoor electrical applications.

🎨 Size and Color Options

HDPE conduit is typically available in black, orange, or red (for communications and power), with standard diameters from 1/2″ up to 6″ or more.

PVC conduit ranges from ½” to 8″ or more. Rigid types are often gray (UL listed), while ENT may be blue, gray or orange depending on region or application.

3. Understanding Wall Thickness and Sizing in HDPE and PVC Conduit

When comparing HDPE and PVC conduits, wall thickness and sizing methods can be a source of confusion — especially since both materials may be listed under UL 651A or UL 651, and may share similar external appearances.

But behind that surface are very different classification systems and structural rules.

We will make a detailed introduction in the following.

📌Under UL 651A, HDPE conduit is classified into several categories, with EPEC, EPEC-A and SCH 40, 80 being the most common.

EPEC (Encased Polyethylene Conduit) is designed specifically for encasement in concrete. This type of conduit follows fixed SDR sizing (such as SDR 9, 11, or 13.5), where lower SDR means thicker walls and stronger resistance.

“A” likely denotes a specific dimensional or performance characteristic within the EPEC family of conduits.

Other standards, such as in NEMA Standards Publication TC 7-2021 Solid-Wall Coilable and Straight Electrical Polyethylene Conduit, EPEC-40, EPEC-80, EPEC-15.5, EPEC-17 also be mentioned.

“Schedule” is a standard pipe sizing system that defines wall thickness in relation to the pipe’s nominal diameter. It’s most commonly associated with PVC conduit, but HDPE conduit can also be manufactured to Schedule dimensions if tested accordingly.

In UL 651, SCH 40, SCH 80, Type EB and A Rigid PVC Conduit are mentioned.

There are also Type DB in other standards.

🔍 Let’s take a closer look at 1/2-inch conduit — one of the most common sizes used in electrical work. We’ll compare the wall thickness between PVC and HDPE conduits for both Schedule 40 and Schedule 80.

📏 For PVC conduit, the minimum wall thickness is 0.109 inches for Schedule 40, and it increases to 0.147 inches for Schedule 80. The thicker wall in Schedule 80 gives it more strength and protection, especially for underground or heavy-duty applications.

🌀 HDPE conduit, on the other hand, is more flexible. At 1/2 inch, it has the same minimum wall thickness as PVC—0.109 inches for Schedule 40 and 0.147 inches for Schedule 80. But HDPE also lists a maximum wall thickness, going up to 0.129 inches (Schedule 40) and 0.167 inches (Schedule 80).

🧱 But the difference is, PVC is a rigid material, so it holds its shape well. It’s great when you need strong, straight runs—like in buildings where the conduit is exposed or in places where it won’t move much after installation.

🔍 Let’s focus on 1/2-inch (16mm) conduit size, a common size across different conduit types. We’re comparing ENT (Electrical Nonmetallic Tubing) and HDPE Schedule 40—both are flexible, but they serve different jobs.

📏 In terms of size, they’re surprisingly close. ENT has an outside diameter of 0.832 to 0.848 inches, and an inside diameter between 0.574 and 0.630 inches. HDPE Schedule 40 has the same outside diameter, but its wall thickness ranges from 0.109 to 0.129 inches, leaving a similar inside space depending on how it’s made.

🧱 ENT is lightweight and easy to work with. You can bend it by hand without heat or tools, which makes it a favorite for indoor installations—especially inside walls, ceilings, or other dry spaces.

🚫 But ENT isn’t built for tough environments. It’s not meant for underground use unless it’s inside another protective conduit. It doesn’t handle impact, pressure, or moisture very well.

🌧️ HDPE Schedule 40, on the other hand, is built tough. It’s water-resistant, impact-resistant, and can be installed directly underground. That makes it ideal for outdoor or buried runs, especially for long-distance cable pulling in telecom or power networks.

⚙️ Installation is different too. ENT is usually cut with a hand tool and snapped into fittings. HDPE often needs fusion welding or compression fittings and is sometimes delivered in long coils for fewer joints.

🔄 Flexibility-wise, both are bendable, but in different ways. ENT bends easily by hand in tight spaces. HDPE bends more gradually and resists kinking, making it great for large-radius sweeps.

4. PVC Conduit vs HDPE Conduit: Strength and Durability

At first glance, HDPE and PVC conduits might appear similar — especially when both come in corrugated or smooth-wall forms.

But beneath the surface, they are made from fundamentally different materials with distinct mechanical behaviors.

That’s why UL 651 and UL 1653 (PVC) and UL 651A (HDPE) take very different approaches when it comes to performance testing.

These standards aim to ensure conduit safety and reliability, but the test items, conditions, and criteria are tailored to the physical nature of each material.

📋 Key Performance Tests: PVC Conduit (UL 651)

| Test Category | غاية |

|---|---|

| قوة الشد | Verifies material integrity during manufacturing |

| امتصاص الماء | Ensures insulation resistance and long-term performance |

| Low-Temperature Handling | Simulates cold-weather installation |

| مقاومة الصدمات | Drop test at sub-zero conditions (−18°C) |

| Deflection Under Load | Measures deformation under long-term pressure |

| مقاومة السحق | Assesses durability under buried or compressed installation |

| Flame Resistance | UL94 Vertical Flame Test (V-0 required) |

| Resistance to Chemicals | Exposure to oil, solvents, etc. |

| Sunlight Resistance | For outdoor-rated conduit |

| Printing Permanence | Verifies lasting identification markings |

PVC conduit testing emphasizes rigidity, dimensional stability, and environmental resistance, especially for Schedule 40 and 80 types.

🌀 Key Performance Tests: HDPE Conduit (UL 651A)

| Test Category | غاية |

|---|---|

| مقاومة الصدمات | Drop test at −32°C, more severe than PVC requirements |

| قوة الشد | Required for joint and material performance |

| Deflection Resistance | Measures long-term creep or deformation |

| Identification of Compounds | Ensures material traceability and batch quality |

| Straightness | Confirms installation ease for long runs |

UL 651A focuses on the flexible nature of HDPE. Unlike PVC, HDPE conduit is coilable and used in longer runs — so the standard emphasizes impact performance at extreme cold, joint integrity, and material flexibility under pressure.

🧰Understanding Test of ENT Under UL 1653

ENT is governed by UL 1653, which sets testing requirements specifically for its lightweight, flexible form and intended installation conditions.

🧪 Key Performance Tests for ENT (UL 1653)

| Test Category | غاية |

|---|---|

| Cold Bend & Impact Resistance | Ensures tubing won’t crack during handling or cold slab pours |

| Flame Resistance (Vertical/FT4) | Verifies fire behavior in vertical spaces or cable trays |

| Pull-Through Wall Studs | Ensures tubing won’t deform or tear during rough-in installation |

| Solvent Fitting Assembly | Checks bonding strength with ENT-specific fittings |

| Resistance to Deflection | Assesses ability to maintain internal clearance under load |

| Durability of Printing | Ensures identification remains legible over time |

5. Applications for PVC Conduit, HDPE Conduit, and ENT

Different conduit types exist for a reason. Whether you’re installing wiring in a high-rise building, burying cables across a wide open field, or embedding them in concrete — the right choice of conduit depends on the jobsite environment and project requirements.

This section breaks down where PVC, HDPE, and ENT conduits are most commonly used, and why.

🧱 Rigid PVC Conduit: Reliable, Durable, and Versatile

Best for: Structural electrical installations, both above and below ground

Commercial and residential buildings

Equipment rooms, electrical closets

Underground duct banks (with or without encasement)

Areas requiring heavy-duty protection or schedule-rated conduit

High crush and impact resistance (especially Schedule 80)

Excellent electrical insulation

Flame-rated and corrosion-resistant

Compatible with standard fittings and boxes

Cost-effective and easy to install with solvent welding

🛠️ PVC is the go-to conduit for contractors needing a strong, rigid solution that complies with building codes and holds up under physical stress.

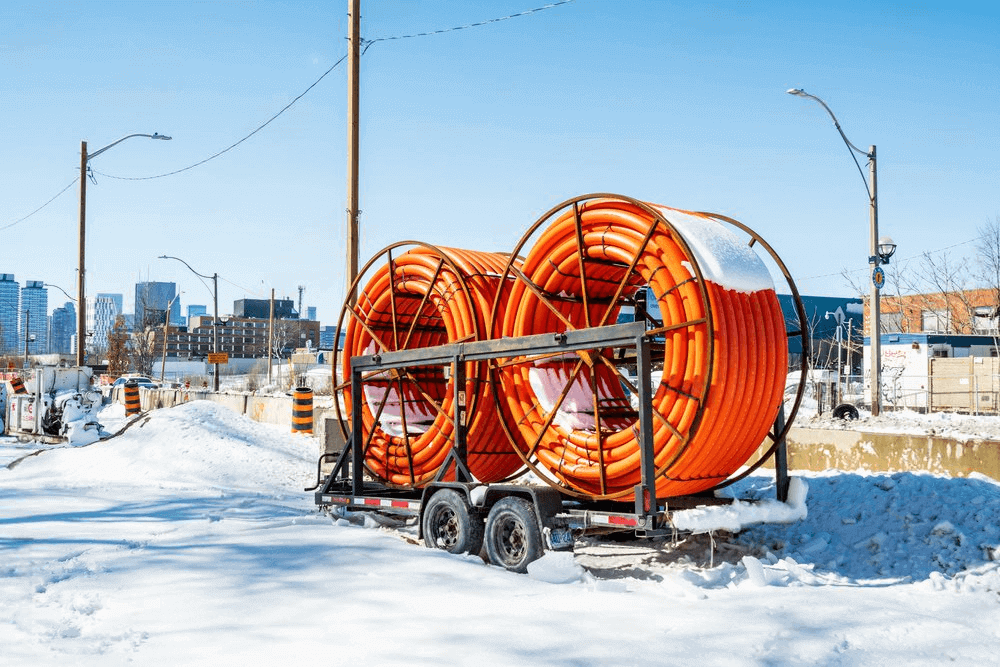

🌱 HDPE Conduit: Flexible, Long-Run, and Built for Harsh Environments

Best for: Underground, outdoor, and directional boring applications

التطبيقات

Utility distribution (power, telecom, fiber)

Long-distance underground runs

Direct burial or concrete encasement

Horizontal directional drilling (HDD) or plowing

Why choose HDPE Conduit?

Flexible and coilable — available in long reel lengths

Fewer joints = faster installs with fewer leak points

Withstands ground movement and temperature extremes

Lightweight and easy to transport

High resistance to chemicals and corrosion

🌍 HDPE conduit is ideal for infrastructure projects where flexibility, long runs, and ground adaptability matter more than rigidity.

🧩 ENT Conduit: Lightweight and Ideal for Concrete Slab Work

Best for: Indoor slab and wall applications where speed and flexibility are key

التطبيقات

Cast-in-place concrete slabs (prewired systems)

Walls and ceilings in commercial or residential buildings

Areas requiring fast installation with minimal labor

Low-voltage or lighting circuits in slab construction

Why choose ENT?

Extremely lightweight and easy to bend

Can be installed quickly — often preassembled

Often includes integrated boxes and fittings

✅ Always match your conduit type to the project demands — don’t choose based on appearance alone. Knowing how each performs in real-world scenarios helps ensure safety, compliance, and efficiency.

6. الخاتمة

HDPE conduit, PVC conduit, and ENT conduits may sometimes look similar — especially when coiled or corrugated — but as we’ve seen throughout this article, their differences run much deeper.

From structural design and wall thickness, to performance testing and real-world behavior, each conduit type follows a unique set of material characteristics and UL standards.

✅ By understanding these distinctions — and the standards behind them — engineers, contractors, and procurement teams can make informed, confident decisions when selecting conduit systems.

Whether your priority is strength, flexibility, ease of installation, or compliance, there’s a conduit that fits your needs — and choosing the right one can save time, reduce risk, and improve long-term performance.

في سي تيوب, we specialize in manufacturing high-quality PVC conduit systems for a wide range of electrical applications. With advanced production lines, UL, CSA، و AS/ NZS 2053 و اللجنة الكهروتقنية الدولية-certified products, and a full portfolio of accessories, we help engineers and contractors build safer, smarter electrical infrastructure — from residential buildings to utility-scale projects.

Whether you need أنبوب صلب for structural use, أنبوب مرن for cable runs, or fast-install solutions for slabs and walls, Ctube delivers reliability, compliance, and innovation in every product.

Thank you for reading! We hope this post is helpful. Wishing you success in your project!