جدول المحتويات

تبديل1. المقدمة

👷 Whether you’re an electrical contractor, a new apprentice, a project manager, or even a hands-on homeowner working on your own wiring—knowing how to use a conduit body can save you time, effort, and mistakes.

❓ So, what exactly is it? A conduit body is a small, hollow fitting that connects electrical conduits.

🔁 It lets you change direction, pull wires more easily, and access your wiring later for maintenance or inspection.

🧩 It’s a simple part—but a really important one in any conduit system.

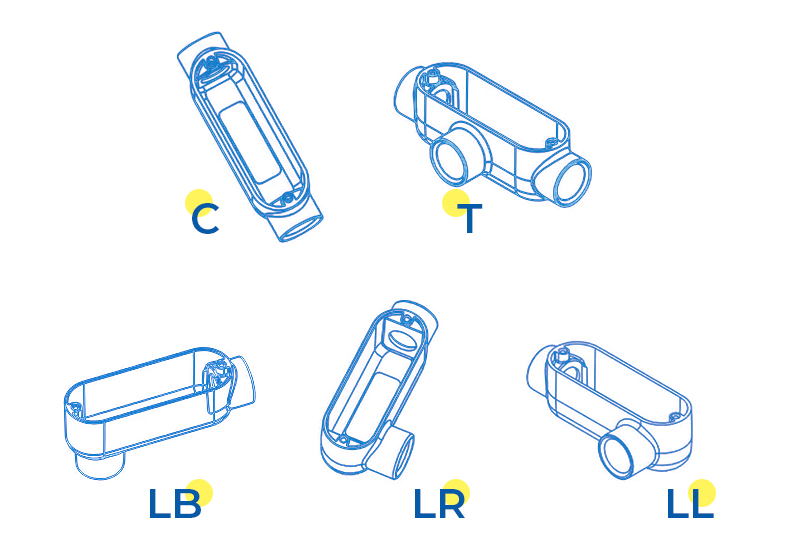

📦 There are several types—like LB, LL, LR, T, and C—and each one serves a different purpose depending on how your conduit is laid out.

📘 In this post, we’ll look at what conduit bodies do, how the different types work, how to choose the right one, and what to keep in mind when installing them.

2. Top 6 Types of Conduit Bodies and How to Use Them

Let’s take a look at the most common types.

🔄 LB Conduit Body

Inlet aligns with the cover, and outlet exits from the back, forming a 90° bend.

This is one of the most widely used conduit bodies. The wires enter from the front and turn out the back, making it perfect for situations where conduit comes up a wall and needs to go into the back of a building. You’ll often see LB bodies near meter bases or outdoor service entrances.

↩️ LL Conduit Body

Inlet aligns with the cover, and outlet exits on the left side.

The LL conduit body lets the conduit come in from one end and turn left. It’s useful when the wiring needs to wrap around a corner or travel left along a wall or ceiling. The cover gives you easy access to the inside of the bend.

↪️ LR Conduit Body

Inlet aligns with the cover, and outlet exits on the right side.

Similar to the LL, but the turn is to the right instead of the left. Use an LR body when your conduit layout takes a right-hand turn—like around a wall corner or between equipment on the right.

🛠️ T Conduit Body

Inlet and outlet hubs form a straight line, with a third branch outlet aligned with the cover (usually perpendicular to the main run).

The T conduit body is shaped like the letter “T.” It lets you run wires straight through while branching off in a third direction. This is helpful when splitting a single conduit line into two—for example, sending one line to lights and another to outlets. The cover usually faces the branch, making it easy to check or pull wires from the junction point.

➖ C Conduit Body

Inlet and outlet are in-line with each other—no change in direction.

This is a straight-through conduit body used mostly for wire pulling and inspection. There’s no turn involved; it simply gives you access to the wiring inside a long, straight conduit run. It’s handy in areas where long distances make pulling wire more difficult.

❌ X Conduit Body

Four conduit hubs—front, back, left, and right—form a cross pattern, with the access cover in the center.

The X conduit body is like a four-way intersection. It lets you connect and access conduit in all four directions. While not commonly used in residential work, it’s sometimes found in commercial ceilings or industrial layouts where multiple conduit lines come together. Be aware that this type may not be allowed everywhere, so check your local code before using it.

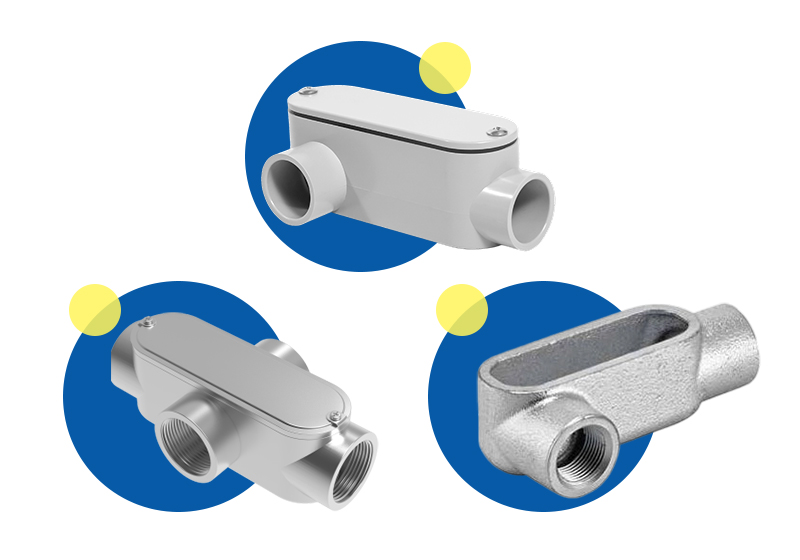

3. Main Materials and Environmental Suitability

Conduit bodies are made from a few key materials — each with its own strengths, surface finish, and ideal application environment. The most common types are aluminum alloy, galvanized steel, and PVC (non-metallic).

Aluminum Alloy Conduit Bodies

Aluminum is a popular material for conduit bodies because it’s lightweight, corrosion-resistant, and easy to handle. Most aluminum conduit bodies are made from die-cast aluminum alloy, which offers good strength while keeping the product relatively light.

To enhance corrosion resistance, many aluminum conduit bodies are powder-coated. This dry powder coating is baked on to create a durable surface that protects against moisture, salt, chemicals, and UV rays. Powder-coated aluminum conduit bodies are well-suited for outdoor installations, wet locations, and coastal environments. The coating also gives the surface a smoother, more professional look — typically in gray or white.

Some aluminum bodies may come without powder coating. These are still corrosion-resistant due to the properties of aluminum, but they are more suitable for indoor use or dry environments, where exposure to harsh elements is limited.

In many cases, aluminum conduit bodies are available with or without gaskets. Gasketed covers provide a tight seal, making them ideal for wet or damp locations. Non-gasketed versions are used in general-purpose applications.

Galvanized Steel Conduit Bodies

Galvanized steel conduit bodies are made from stamped or cast steel with a layer of zinc added to prevent rust. This zinc coating is applied through a hot-dip galvanizing or electroplating process. The result is a durable, impact-resistant body with good mechanical strength.

Some steel bodies are also powder-coated on top of the zinc layer, offering dual protection. These are suitable for industrial environments, especially where strength and surface durability are important — such as in mechanical rooms, manufacturing plants, or exposed outdoor areas.

Non powder-coated steel bodies rely solely on the zinc layer. They are best used indoors or in dry areas, as they may eventually rust if the zinc coating gets damaged in a corrosive setting.

Galvanized steel conduit bodies tend to be heavier than aluminum and are less commonly used in environments where corrosion is a major concern.

PVC (Non-Metallic) Conduit Bodies

PVC conduit bodies are made entirely from plastic (polyvinyl chloride) and offer a completely non-metallic, non-conductive solution. They are naturally resistant to moisture, acids, alkalines, and most chemicals.

PVC conduit bodies are commonly used in wet, corrosive, or underground environments — such as water treatment facilities, food processing plants, or near coastal areas. Because they do not rust, they are ideal where metal corrosion is a concern.

The body and cover are usually sealed tightly using PVC gaskets or compression fittings, providing a weatherproof or watertight seal. However, PVC is not suitable for high-temperature or high-impact locations and should be protected from direct UV exposure unless rated for outdoor use.

4. How to Choose the Right Conduit Body

Choosing the right conduit body isn’t just about shape—it also depends on the conduit type, connection method, environment, and code requirements. Making the right decision ensures smoother installation, easier maintenance, and full code compliance.

📍 Match the Conduit Path

The first step is understanding how your conduit needs to move.

For a 90° turn into a wall or enclosure, use an LB body.

If you’re turning left or right around a corner, choose an LL or LR.

For a three-way branch, use a T body.

If you need to connect four directions, consider an X body.

In long straight runs, a C body offers a mid-point access for pulling wires.

Each type is designed to maintain proper bend radius while allowing access to conductors at key points.

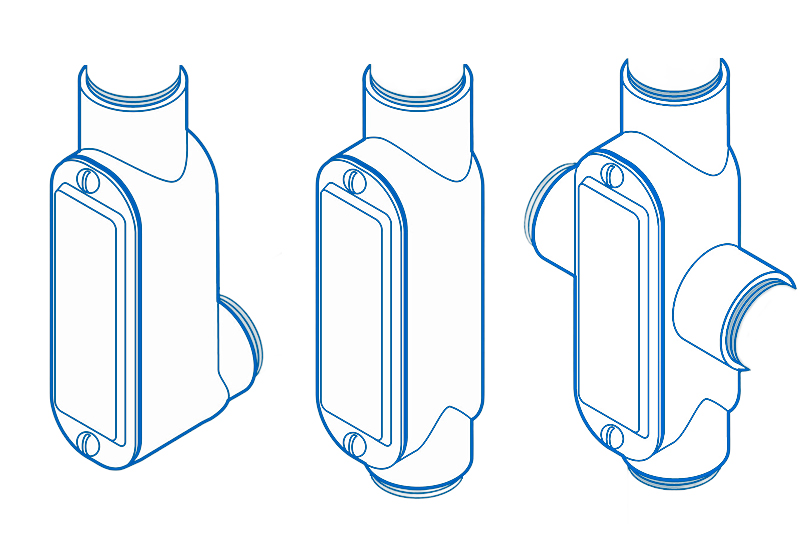

📐 Select the Right Connection Type

Conduit bodies are available in both threaded and non-threaded (smooth) versions. The type you choose must match the conduit material and connection method:

Threaded hubs are used with rigid metal conduit (RMC), intermediate metal conduit (IMC), or EMT fittings. These bodies screw onto threaded conduit ends or threaded adapters.

Smooth hubs are used with PVC conduit, joined using solvent cement. These bodies are designed for glue-in connections and do not have internal threads.

It’s critical to use the correct hub type. Attempting to glue into threads or force threaded conduit into a smooth hub may lead to poor connections, leaks, or code violations.

🧱 Choose a Suitable Material for the Environment

Conduit bodies are made from materials that perform differently in various settings:

Aluminum and die-cast zinc are lightweight, corrosion-resistant, and suitable for indoor or light-duty outdoor use.

Malleable iron or cast steel provides high durability and is often used in industrial or hazardous locations.

PVC (non-metallic) is ideal for wet, buried, or corrosive environments. When paired with watertight covers and gaskets, PVC conduit bodies offer excellent long-term sealing.

For outdoor, underground, or washdown areas, non-metallic options are often preferred due to their resistance to rust and chemical damage.

📏 Confirm Hub Size and Box Capacity

Each conduit body must be properly sized to fit the conduit system. Hub sizes range from ½” to 4″ or more, and should match the outer diameter of your conduit. Also, consider the internal volume of the body, especially when splicing or pulling multiple conductors.

Use the manufacturer’s cubic inch rating to ensure there’s enough space for wire bends and terminations.

If wire fill is tight, opt for a deep version of the body to give yourself more room.

Proper sizing avoids overheating, physical damage, and failed inspections.

📘 Meet Code Requirements

Always check local electrical codes before selecting a conduit body. The NEC (Article 314) outlines requirements for accessibility, volume, and environmental sealing. Key rules include:

Conduit runs over certain lengths must include accessible pull points

Covers must be removable without damaging walls or finishes

In wet locations, conduit bodies must be listed as weatherproof and used with gaskets

Some regions restrict the use of certain materials or shapes (like X bodies) in specific environments, so it’s important to verify compliance early in the design phase.

5. الخاتمة

Conduit bodies may seem like small components in an electrical system, but their impact on wiring layout, maintenance access, and code compliance is significant.

By understanding the function of each type, you can make smarter layout decisions and avoid costly rework.

Matching the correct hub size and connection type to your conduit ensures safe and secure installations, while selecting the right material keeps the system durable under environmental stress.

Whether you’re working on a residential build, a commercial retrofit, or an industrial project, choosing the right conduit body simplifies your work and supports a clean, serviceable system.

With proper planning, the right fittings not only improve efficiency on-site but also guarantee your installation stands up to inspection and time.

في سي تيوب, we specialize in providing high-quality PVC conduit bodies designed to meet a wide range of installation needs. Our conduit bodies come in multiple standard shapes—including LB, LL, LR, T, and C—and are manufactured with smooth solvent-weld hubs and built-in gaskets to ensure secure, watertight connections, especially in outdoor or damp environments.

In addition to our standard offerings, we also support custom solutions to match your unique project requirements—whether that means non-standard hub sizes, special angles, or labeling. Our focus is on helping electricians, contractors, and system designers build safer, cleaner, and more efficient conduit systems.

Thank you for reading this article—we hope it has helped you better understand how to choose and use conduit bodies. If you have further questions or specific project needs, feel free to reach out to our team. We’re here to support you with practical products and professional advice.

الأسئلة الشائعة

Q1: Can a conduit body be installed outdoors?

Yes, conduit bodies can be installed outdoors, but you must ensure they are rated for wet locations.

For outdoor use, the conduit body should be marked “wet location” or “raintight” and be used with a gasketed cover to maintain a proper seal. In exposed environments, using non-metallic (PVC) conduit bodies with solvent-welded joints or corrosion-resistant metallic bodies is recommended.

Always confirm the product has the appropriate UL or CSA listings for your application.

Q2: How do I know whether to use an LB or an LL?

The choice between an LB and an LL depends on the direction your conduit needs to turn.

An LB conduit body makes a 90-degree turn from the front to the back—often used when conduit runs along a wall and needs to go into a building.

An LL conduit body also makes a 90-degree turn, but the outlet turns to the left side when you’re facing the cover.

It’s helpful to visualize the wire path: if it needs to go straight then left, use an LL; if it needs to enter straight and turn inward (toward a wall), choose an LB.

Q3: Can a conduit body be used as a junction box?

In some cases, yes. Conduit bodies can serve as a junction point for splicing or tapping conductors, but only if the internal volume is sufficient and local code allows it.

The National Electrical Code (NEC) permits splicing in conduit bodies as long as they meet the required cubic inch space for the conductors involved and remain accessible after installation.

However, they are not a replacement for full-sized junction boxes in situations with large wire counts or high-current connections.

Q4: Do I need to use sealant when installing the cover?

If the conduit body is installed in a wet or outdoor location, you should use a gasketed cover and, in some cases, apply a non-hardening sealing compound around the cover screws or edges to improve watertightness.

Many weatherproof covers come with a factory-installed gasket, but if not, you can purchase gaskets separately.

For indoor dry locations, standard screw-on covers are usually sufficient without additional sealant, unless specified by the product instructions.