جدول المحتويات

تبديل1. المقدمة

🔌 When it comes to protecting electrical wiring in residential, commercial, or industrial projects, Schedule 40 PVC conduit is one of the most widely used and trusted solutions.

Known for its durability, corrosion resistance, and cost-effectiveness, Schedule 40 conduit is a go-to option for both above-ground and underground installations.

🚧But what exactly does “Schedule 40” mean? How does it compare to other types of conduit, such as Schedule 80 or rigid metal conduit?

What certifications—like UL listing or NEC compliance—should you look for? And how deep does it need to be buried for safe and legal use?

💡 Whether you’re a licensed electrician, a project engineer, or a procurement manager, this guide will walk you through everything you need to know about Schedule 40 PVC conduit.

From detailed specifications and performance testing to installation depth and standards compliance, we’ll help you make informed choices and ensure your electrical system is built to last.

2. What Does “Schedule” & “40” Mean in the Context of Schedule 40 PVC Conduit?

You’ve probably seen the term “Schedule 40” printed on PVC conduit before. But what does it actually mean?

🤔 Is it a size? A strength rating? A pressure code? Let’s break it down together.

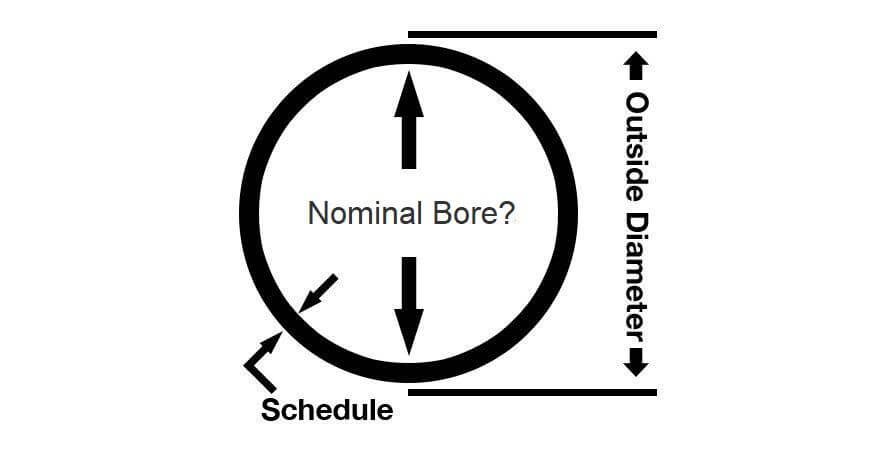

🧱 What Does “Schedule” Mean?

The word “Schedule” refers to a standardized code used to define the wall thickness of a pipe or conduit. It doesn’t measure pressure directly, but thicker walls often mean the conduit can handle more impact or stress.

✅ Think of “Schedule” as a way to classify pipes by how thick and strong the walls are—and it depends on the pipe’s Nominal Pipe Size (NPS).

📏 What Is Nominal Pipe Size (NPS)?

NPS stands for Nominal Pipe Size, and it’s used in North America to describe the outer diameter of pipes.

The outer diameter (OD) stays the same for each nominal size (like 2″, 3″, 4″).

The wall thickness changes depending on the Schedule (like 40 or 80).

Schedule 40 conduit is commonly used in residential homes 🏠, commercial buildings 🏢, and light-duty underground installations 🚧.

It’s a versatile choice that meets key industry standards, including UL 651 for electrical conduit and ASTM D1785 for pressure-rated plastic pipes.

Which means… the inner diameter (ID) also changes.

🧮 For example:

A 2-inch Schedule 40 PVC conduit has an OD of 2.375″ and a wall thickness of 0.154″.

So its inner diameter is about 2.067″.

So no, a 2-inch pipe doesn’t always have a 2-inch hole inside 😄.

🔢 What Does “Schedule 40” Actually Tell You?

“Schedule 40” means the conduit has a medium wall thickness—thick enough for most electrical installations, but still light and easy to handle.

Schedule 40 conduit is commonly used in residential homes 🏠, commercial buildings 🏢, and light-duty underground installations 🚧.

It’s a versatile choice that meets key industry standards, including UL 651 for electrical conduit and ASTM D1785 for pressure-rated plastic pipes.

3. What Are the Key Specifications for Schedule 40 PVC Conduit?

🧱 Material Composition: Schedule 40 electrical conduit is made from rigid polyvinyl chloride (PVC), a thermoplastic.

📐 Standard Dimensions

| Size (in) | OD (in) | ID Min Avg (in) | Wall Thickness Min (in) |

|---|---|---|---|

| 1/2″ | 0.840 | 0.578 | 0.109 |

| 3/4″ | 1.050 | 0.780 | 0.113 |

| 1″ | 1.315 | 1.004 | 0.133 |

| 1-1/4″ | 1.660 | 1.335 | 0.140 |

| 1-1/2″ | 1.900 | 1.564 | 0.145 |

| 2″ | 2.375 | 2.047 | 0.154 |

| 3″ | 3.500 | 3.068 | 0.216 |

| 4″ | 4.500 | 3.826 | 0.237 |

| 6″ | 6.625 | 5.958 | 0.280 |

| 8″ | 8.625 | 7.853 | 0.322 |

📌 Note: This table is for reference only. Actual dimensions can vary slightly between manufacturers — and that’s totally okay, as long as they fall within the tolerances defined by UL and NEMA standards.

📏 Length & Joining: These conduits are available in 10-foot (3.05 meter) straight lengths, with one end belled to allow for easy joining using solvent cement. Some versions are also designed with integrated coupling ends, making installation even more convenient.

4. What are the Detailed Testing Requirements for Schedule 40 PVC Conduit ?

When you’re choosing Schedule 40 PVC conduit for an electrical job, it’s not just about size or wall thickness — safety and quality matter just as much.

So how do you know if a conduit is safe to use? That’s where certifications like UL 651 come in.

Let’s walk through what these standards mean — and why you should care.

🔎 What Is UL 651?

UL stands for Underwriters Laboratories, a trusted organization that tests products for safety and performance.

💡 Think of UL 651 as a stamp of approval — it shows the conduit is tested, trusted, and ready for use in real-world electrical systems.

To ensure safety and performance, Schedule 40 PVC conduit must meet strict testing requirements before it can carry the UL 651 certification label.

🧱 Material and Workmanship

Before anything else, let’s talk about what Schedule 40 PVC conduit is actually made of.

To be UL-listed, the material must meet a high standard known as ASTM D1784, which sets the rules for what kind of PVC compound is allowed.

Specifically, Schedule 40 rigid PVC conduit must meet or exceed a cell classification of 12123—a code that defines the material’s strength, flexibility, and resistance to heat and impact.

✅ ASTM D1784-20 Requirements for PVC Compounds

According to ASTM D1784-20, the PVC compound used for Schedule 40 conduit must meet strict performance criteria in the following areas:

- قوة الشد – how much the material can stretch before breaking

- مقاومة الصدمات – how well it handles being dropped or struck

- معامل المرونة – the stiffness or flexibility of the material

- درجة حرارة الانحراف – how the material performs when exposed to heat

- قابلية الاشتعال – how the material reacts to fire or ignition sources

The raw PVC material is typically supplied as cubes, granules, or powder. It must be:

- Clean and uniform in appearance

- Free from any contamination or foreign substances

During manufacturing, safe additives may be included in the compound to enhance processing and performance. Common additives include:

- Lubricants

- المثبتات

- Color pigments

- Fillers – to improve structure or processing characteristics

As long as the final PVC compound contains at least 80% vinyl chloride and passes all required tests, it is approved for use in the production of Schedule 40 electrical conduit.

👉 In short, this means every conduit starts with high-quality, carefully tested material—so you can count on long-lasting, reliable performance.

📏 أبعاد

When it comes to conduit, size matters—and not just for fitting wires inside. To meet UL 651 and ASTM standards, Schedule 40 PVC conduits must follow strict rules about their outside diameter (OD), wall thickness, and length tolerances. This ensures consistency, safety, and compatibility with fittings and other conduit systems.

📌 Note: As we mentioned above, the exact measurements—such as OD, wall thickness, and length tolerance—can vary slightly between manufacturers. That’s totally fine, as long as the product stays within the allowable tolerances defined by UL 651 or ASTM standards.

🔬 Test Conditions

Before any performance testing begins, Schedule 40 PVC conduit samples must go through a preconditioning process. This step ensures that test results are fair, accurate, and consistent—no matter which manufacturer or lab is doing the testing.

🕒 What does preconditioning mean?

It simply means placing the test samples in a stable environment for a certain period before testing. For Schedule 40 PVC conduit, here’s the requirement:

All specimens must be stored for at least 24 hours in still air, at a temperature of

23.0 ±2.0°C (73.4 ±3.6°F) before any performance tests are conducted.

This standard condition helps eliminate the influence of recent manufacturing, transportation, or environmental exposure. It allows the material to “settle” into a normal state, so the tests reflect how the product will behave in real-world installations.

🌡️ Why this temperature?

The 23°C (or 73.4°F) is known as room temperature in testing standards. It’s a global benchmark used across many material and product evaluations to ensure consistency.

✅ What kinds of tests use this condition?

Almost all performance tests—like impact resistance, crush strength, tensile strength, and flammability—require the samples to be preconditioned this way. It’s part of the UL 651 and ASTM testing protocols to guarantee reliable results.

🔬 How Is Schedule 40 Conduit Tested?

| امتحان | متطلبات |

|---|---|

| قوة الشد | 5,000 psi (34.5 MN/m²) (3.45 kN/cm²) (3515 gf/mm²) for Schedule 40 |

| امتصاص الماء | Finished Schedule 40 shall not absorb more than 0.50% of its own weight after 24 hours in distilled water |

| مقاومة الصدمات | Shall not crack or tear longer than 1/32 inch (0.8 mm) along the outer surface |

| Flame Resistance | Vertical specimens shall not flame for longer than 5 seconds after any of three 60-second flame applications (with 30-second intervals) |

| Sunlight Resistance | After 720, 1080, or 1440 hours of conditioning, shall maintain average Izod impact strengths* |

* Only part of the contents are listed for reference only. Please refer to UL 651 for full details.

* The Izod impact strength test is an ASTM standard method for determining impact resistance.

اختبار قابلية الاشتعال

UL 94 tests the material’s reaction to flame and classifies it based on how quickly it extinguishes.

| فصل | Orientation of Test Sample | تعريف | الوقت المسموح به للحرق | Practice Drop Allowed | ثقوب اللويحة |

|---|---|---|---|---|---|

| UL 94 HB | أفقي | حرق بطيء | Burning rate of less than 76mm/min for a specimen less than 3mm thick and burning stops before 100mm | / | / |

| UL 94 V-2 | رَأسِيّ | توقف الحرق | الثلاثينيات | Flaming: Yes Non-Flaming: Yes |

/ |

| UL 94 V-1 | رَأسِيّ | توقف الحرق | الثلاثينيات | Flaming: No Non-Flaming: Yes |

/ |

| UL 94 V-0 | رَأسِيّ | توقف الحرق | 10 ثانية | Flaming: No Non-Flaming: Yes |

/ |

| UL 94 5VB | رَأسِيّ | توقف الحرق | الستينيات | Flaming: No Non-Flaming: No |

نعم |

| UL 94 5VA | رَأسِيّ | توقف الحرق | الستينيات | Flaming: No Non-Flaming: No |

لا |

التصنيفات هي كما يلي:

The Canadian Electrical Code (CEC), published by the Canadian Standards Association, is the Canadian safety code for electrical installations that is adopted into law by each province and territory with amendments or local rules.

The Code includes references to an astringent series of tests developed for lame testing of wires and cables. Cables are marked from FT1 to FT6, depending on which of the specified flame test requirements they fulfill.

وفيما يلي تفاصيل طرق الاختبار ومعايير التقييم:

| امتحان | Set Up | Flame Output | Duration | Pass/Fail Criteria |

|---|---|---|---|---|

| FT1 | رَأسِيّ | 3,000 BTU/hour | 5×15s | A finished conductor shall not convey flame or continue to burn for more than 60 seconds after five 15-second applications of the test flame. If more than 25% of the extended portion of the indicator is burned, the conductor shall be considered to have conveyed flame. |

| FT2 | أفقي | 1,700 BTU/hour | الثلاثينيات | The length of the charred portion of the specimen of cord shall not exceed 100 mm nor shall it drop flaming particles. |

| FT4 | رَأسِيّ | 70,000 BTU/hour | 20 min | Finished wires or cables shall not exhibit charred material beyond a length exceeding 1.5 m (5 ft) from the lower edge of the burner face when subjected to the test. |

| FT5 | أفقي | 1,700 BTU/hour | الستينيات | The cable shall not have a length of burned area exceeding 150 mm and shall not continue to burn for more than four minutes when subjected to the flame test. |

| FT6 | أفقي | 300,000 BTU/hour | 20 min | A flame travel distance not exceeding 1.52 m (5 ft), a peak optical density of smoke not exceeding 0.5, and an average optical density not exceeding 0.15 are described as having adequate fire-resistant and low smoke-producing characteristics. |

مقاومة الأشعة فوق البنفسجية

When plastic materials are exposed to sunlight for long periods, the UV (ultraviolet) rays can break down their molecular structure.

🌞 This process is called photodegradation, and it’s a big problem for outdoor plastics like electrical conduits.

Here’s what happens:

UV rays damage the chemical bonds in the plastic.

This creates free radicals—tiny, unstable atoms that attack nearby molecules.

⚠️As the damage spreads, the plastic starts to crack, discolor, and lose strength and flexibility.

And when that happens? It puts your electrical cables at serious risk, especially in outdoor or exposed installations.

To make sure plastic conduits can survive years of sun exposure without failing, manufacturers do special UV testing.

🌤️ This test simulates long-term sunlight exposure (like 8 years!) in a short amount of time—about 480 hours in a lab.

The test checks for things like:

🔹 Color fading

🔹 Loss of impact strength

🔹 Reduced flexibility or brittleness

🌎✅ What’s tested can vary depending on the application, but the goal is always the same: to make sure the material can hold up under sunlight, just like it would in real life.

Marking

🛠️✅Every piece of Schedule 40 PVC conduit must have clear and permanent markings on it. These markings aren’t just for show — they tell you important information and help make sure everything is up to code.

Here’s what the marking includes:

✅ The UL symbol – this means the conduit has been tested and approved under UL 651, a trusted safety standard.

🔤 The type of conduit (e.g., “Schedule 40 PVC”).

📘 The UL standard number.

🏭 The manufacturer’s name.

📏 The conduit size (like 1/2″, 1″, etc.).

These markings help installers and inspectors quickly verify that the conduit is certified and suitable for the job. No guesswork needed!

5. What are the Common Applications of Schedule 40 PVC conduit?

Schedule 40 PVC conduit is a versatile and durable choice for running electrical wiring. Thanks to its moisture resistance and toughness, it can be installed above ground or underground, and works well in a variety of environments.

🏡In Residential Homes

Schedule 40 PVC is commonly used to run electrical wires through homes—inside walls, basements, attics, and garages. It’s also great for outdoor applications like garden lighting, landscape power lines, and pool wiring, where the conduit needs to resist moisture and weather. Homeowners love it because it’s lightweight, easy to cut, and long-lasting.

🏬In Commercial Buildings

In places like offices, shops, and public buildings, this conduit helps route both power and communication cables. You’ll find it hidden behind walls, ceilings, and under floors. It’s a cost-effective and easy-to-install option, making it perfect for both new buildings and remodel projects.

🏗️In Industrial Facilities

Factories and warehouses also rely on Schedule 40 PVC conduit. It helps protect wires from chemicals, moisture, and physical impacts—all of which are common in industrial environments. Whether it’s heavy-duty equipment or automated systems, this conduit keeps cables safe and running smoothly.

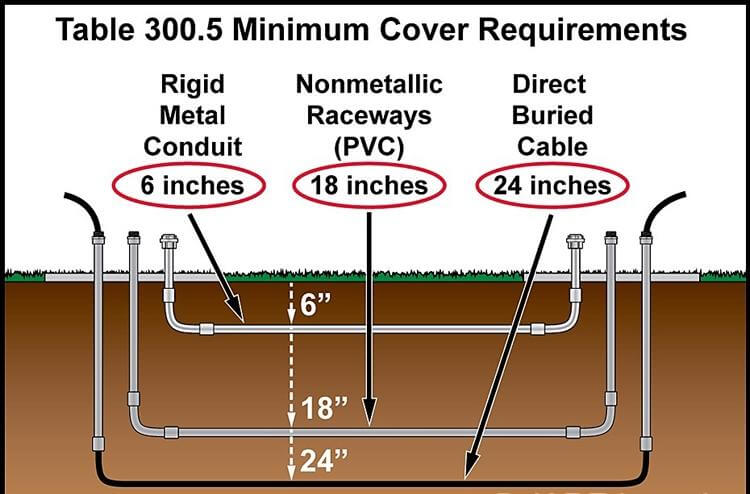

6. How Deep should Schedule 40 PVC Conduit be Buried Underground?

🌱🛠️If you’re planning to run Schedule 40 PVC conduit underground, you’ll need to follow burial depth guidelines to keep your installation safe and up to code. These depths are based on recommendations from the National Electrical Code (NEC) and help prevent accidental damage from digging or heavy loads.

| نوع التثبيت | Minimum Burial Depth | Explanation |

|---|---|---|

| الدفن المباشر | 18 inches (45 cm) | Conduit placed directly in soil must be at least 18″ deep to protect against tools, digging, and surface loads. |

| Concrete Encasement | 6 inches (15 cm) | When conduit is encased in concrete, the required depth is reduced due to added protection. |

| Under a 2-inch Concrete Slab | 12 inches (30 cm) | If installed under a concrete slab at least 2″ thick, 12″ depth is acceptable because the slab offers moderate shielding. |

| 💡 Pro Tip: Always check local codes or utility regulations—some areas may have stricter rules than the NEC! | ||

What Affects How Deep Should Bury Conduit?

🌍🚧 While the NEC provides general rules for how deep to bury Schedule 40 PVC conduit, the actual depth may need to be adjusted depending on site-specific conditions. Here are some key factors to consider before you start digging:

| عامل | Explanation |

|---|---|

| Soil Type | – Loose or sandy soil may shift, so deeper burial helps maintain stability. – Dense or compacted soil offers better natural support, requiring less depth. |

| Freezing Temperatures (Frost Line) | – In cold regions, conduit must be buried below the frost line. – Freeze-thaw cycles can move soil, risking conduit damage. – Check local building codes or regional frost data. |

| Traffic Loads | – If installed under driveways, roads, or parking lots, conduit may need deeper burial or concrete encasement. – This prevents damage from pressure and vibration. |

| Installation Method | – Direct burial needs more depth due to exposure to the elements. – Concrete encasement allows shallower burial by adding protection. |

✅ Tip: Always consult your local electrical code or a licensed electrician to confirm the exact requirements for your area. They may differ from the NEC based on regional conditions.

| ARTICLE 300 — GENERAL REQUIREMENTS FOR WIRING METHODS AND MATERIALS | |||||

|---|---|---|---|---|---|

| Table 300.5 Minimum Cover Requirements, 0 to 1000 Volts, Nominal, Burial in Millimeters (Inches) (Type of Wiring Method or Circuit) |

|||||

| Location of Wiring Method or Circuit | Column 1 Direct Burial Cables or Conductors |

Column 2 Rigid Metal Conduit or Intermediate Metal Conduit |

Column 3 Nonmetallic Raceways Listed for Direct Burial |

Column 4 Residential Branch Circuits Rated 120V or Less with GFCI |

Column 5 Circuits for Control of Irrigation and Landscape Lighting |

| mm / in. | mm / in. | mm / in. | mm / in. | mm / in. | |

| All locations not specified below | 600 / 24 | 150 / 6 | 450 / 18 | 300 / 12 | 150a,b / 6a,b |

| In trench below 50 mm (2 in.) thick concrete or equivalent | 450 / 18 | 150 / 6 | 300 / 12 | 150 / 6 | 150 / 6 |

| Under a building | 0 | 0 | 0 | 0 (in raceway or Type MC or MI) | 0 (in raceway or Type MC or MI) |

| Under min. 102 mm (4 in.) thick concrete slab with no traffic & 152 mm (6 in.) beyond installation | 450 / 18 | 100 / 4 | 100 / 4 | 150 / 6 (direct burial) 100 / 4 (in raceway) |

150 / 6 (direct burial) 100 / 4 (in raceway) |

| Under streets, highways, roads, alleys, driveways, and parking lots | 600 / 24 | 600 / 24 | 600 / 24 | 600 / 24 | 600 / 24 |

| One- and two-family dwelling driveways and outdoor parking (dwelling only) | 450 / 18 | 450 / 18 | 450 / 18 | 300 / 12 | 450 / 18 |

| In or under airport runways, including adjacent no-trespassing areas | 450 / 18 | 450 / 18 | 450 / 18 | 450 / 18 | 450 / 18 |

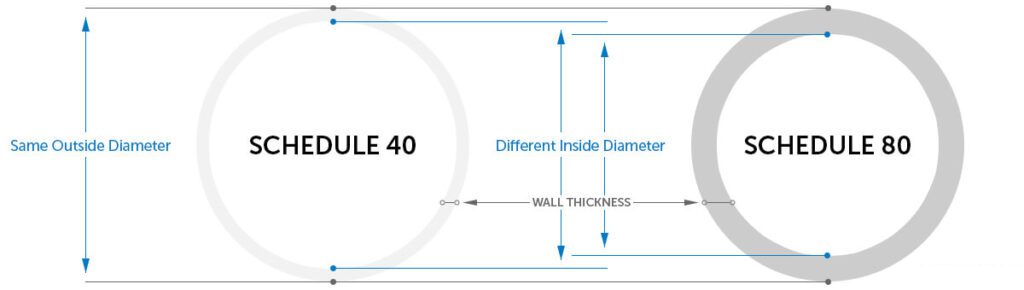

7. What’s the Difference Between Schedule 40 and Schedule 80 PVC Conduit?

🔍Both Schedule 40 and Schedule 80 PVC conduits are used to protect electrical wiring—but they’re built a bit differently, and each one is better suited for certain types of jobs.

Let’s take a closer look at how they compare:

| فئة | الجدول الزمني 40 | الجدول 80 |

|---|---|---|

| سمك الجدار | Has a thinner wall, which makes it lighter and easier to handle. It’s ideal for most residential and light commercial uses where extreme durability isn’t required. | Features a thicker wall, giving it more strength and impact resistance. This extra durability helps protect wires in rougher environments. |

| Pressure and Impact Resistance | Works well in areas where the conduit won’t be exposed to heavy pressure or physical damage. Great for general use in homes and buildings. | Has a higher pressure rating and is built to withstand harsher conditions, such as in industrial sites or areas with a risk of impact. |

| يكلف | More budget-friendly because it uses less material. It’s a smart choice for most standard jobs where extreme strength isn’t needed. | Typically more expensive due to its thicker construction and improved durability. |

| Installation Difficulty | Easier and faster to install thanks to its light weight and flexibility. It’s easier to cut and bend too. | Tougher to work with because of the thicker wall. It may require more effort and tools during installation. |

8. Conclusion

جدول 40 أنابيب PVC remains a trusted choice in residential, commercial, and even some light industrial electrical installations. Its balance of durability, ease of use, and cost-effectiveness makes it a go-to solution for protecting electrical wiring above ground, underground, or embedded in concrete.

By understanding the relevant standards, installation requirements, and the differences between Schedule 40 and other conduit types like Schedule 80 or RMC, electricians and contractors can ensure safe, compliant, and long-lasting electrical systems.

Whether you’re planning a small project or managing a large infrastructure job, choosing high-quality, certified products—like those offered by Ctube—can make all the difference in performance and safety.

سي تيوب’s Schedule 40 and Schedule 80 rigid PVC conduits are UL and CSA certified, offering dependable performance across residential, commercial, and industrial applications.

With additional global certifications such as SGS, RoHS, CE, and IEC, Ctube products meet international standards and are trusted for their durability, safety, and long-lasting quality.

Thank you for reading. We hope this guide has been helpful and wish you success with your project.

For any project inquiries or further assistance, contact us.

الأسئلة الشائعة

Q1: What’s the difference between Schedule 40 electrical conduit and Schedule 40 plumbing pipe?

40 electrical conduit is made to protect wires. It’s UV-resistant, flame-retardant, and has a smooth interior to help with wire pulling. It follows electrical safety standards.

Schedule 40 plumbing pipe is used for water or fluid transport. It focuses on pressure resistance and meets plumbing codes.

Even if they look similar, they are made for different purposes and should not be used interchangeably.

Q2: What tools do I need to cut and install Schedule 40 electrical conduit?

Tape measure – for accurate length.

PVC cutter or hacksaw – to cut the conduit.

Deburring tool or utility knife – to smooth edges after cutting.

Conduit bender – if bends are needed.

Fittings – like elbows, couplings, or adapters.

PVC solvent cement – to join conduit and fittings.

Marker – to mark where to cut or align parts.

Q3: How is Schedule 40 PVC conduit different from rigid metal conduit (RMC)?

Schedule 40 PVC is plastic, lightweight, corrosion-resistant, and affordable. It’s easier to work with but offers less physical protection.

Rigid metal conduit is made of steel or aluminum. It’s heavy, more durable, and offers better protection, but it’s harder to install and costs more.

Choose PVC for lighter-duty or outdoor work, and RMC for high-impact or industrial areas.