Tabla de contenido

Palanca1. Introducción

In electrical installations, conduit selection plays a critical role in ensuring long-term safety, code compliance, and project efficiency.

While choosing the correct conduit size and material is standard practice, one often overlooked decision is whether to use Schedule 40 or Schedule 80 PVC conduit.

This post is written for contractors, electricians, project engineers, and inspectors who want a clear and practical understanding of when Schedule 80 PVC conduit is required—or strongly recommended.

Whether you’re working on a residential upgrade, a commercial facility, or an industrial site, understanding when to use thicker-walled Schedule 80 can help you avoid inspection issues, ensure durability, and meet NEC requirements.

2. What Is Schedule 80 PVC Conduit?

Schedule 80 PVC conduit is a rigid, non-metallic raceway made from polyvinyl chloride (PVC), designed to protect and route electrical wiring in commercial, industrial, and other high-risk environments.

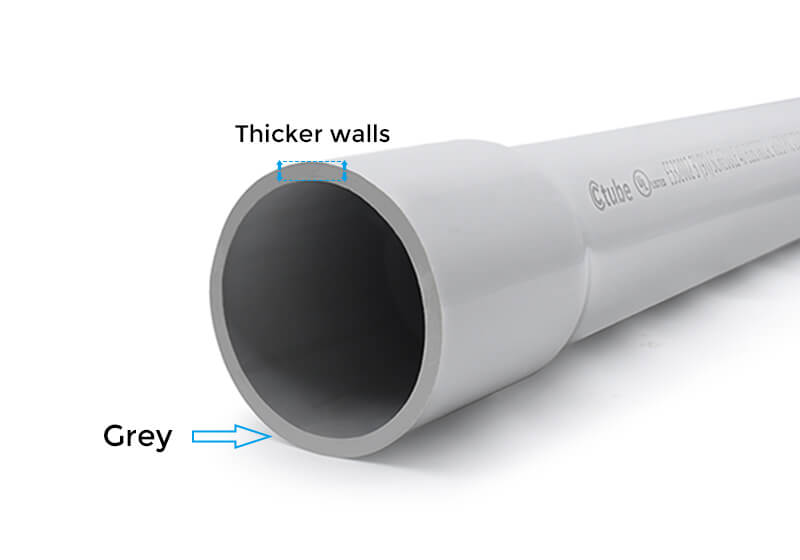

In appearance, Schedule 80 is typically dark gray, same as Schedule 40.

Compared to its counterpart, Schedule 40, Schedule 80 has a thicker wall, providing greater mechanical strength and resistance to physical damage.

Because of its thicker walls, Schedule 80 has a smaller internal diameter than the same nominal size of Schedule 40, which can slightly affect conduit fill and wire pulling.

3. When Is Schedule 80 PVC Conduit Required?

The National Electrical Code (NEC) sets clear expectations for when Schedule 80 PVC conduit must be used—and it all comes down to exposure to physical damage.

According to NEC Article 352.10(F), when rigid PVC conduit is exposed to physical damage, only Schedule 80 is permitted. This means that if a conduit run is installed in an area where it could be bumped, struck, or crushed—either accidentally or due to environmental factors—you’re required to upgrade from Schedule 40 to Schedule 80.

But what exactly qualifies as “exposed to physical damage”? The code doesn’t give a one-size-fits-all answer, which is why electricians and inspectors must rely on context, experience, and local code interpretation.

⚠️ Common Scenarios Where Schedule 80 Is Required:

Exposed conduit on building exteriors (especially near ground level)

Conduit runs in commercial or industrial workspaces near forklifts, carts, or machinery

Vertical conduit risers on utility poles or side walls, where equipment or vehicles may impact them

Conduit passing under driveways, roads, or areas with vehicle traffic

Outdoor generator or HVAC installations, where conduit is exposed and unprotected

In these situations, Schedule 40 conduit could be too fragile, and failure could lead to damaged wiring, downtime, or worse—electrical hazards.

🏢 Commercial and Industrial Facilities

In warehouses, manufacturing plants, and distribution centers, conduit is often installed along exposed walls or columns. These areas are at high risk of accidental impact from forklifts, pallet jacks, or maintenance equipment.

In these environments, Schedule 80 is frequently required—not just by code, but by insurance and safety standards as well. Using Schedule 40 in such areas could lead to premature conduit failure and failed inspections.

🏠 Residential Driveways and Garages

When running conduit underground beneath driveways or slabs, or exposed in residential garages where cars and tools move regularly, Schedule 80 provides added durability against crushing or surface impact.

While code may still allow Schedule 40 if burial depth is adequate, many electricians choose Schedule 80 to protect against the unknowns—such as future landscaping or equipment placement.

🌧️ Outdoor Installations

Anytime conduit is installed on the exterior of a building, especially below 8 feet where it can be touched or bumped, it’s often considered “exposed to physical damage.” This includes service risers, generator hookups, outdoor lighting runs, and HVAC unit wiring.

Some local codes or inspectors even require all above-grade outdoor PVC to be Schedule 80, regardless of location.

🚧 Utility and Infrastructure Projects

For electrical lines routed along utility poles, streetlight bases, or roadside enclosures, Schedule 80 is the standard choice due to the constant risk of physical abuse and weather exposure. The thicker wall adds both strength and extended service life.

4. Where Is Schedule 80 PVC Conduit Commonly Used?

Schedule 80 PVC conduit is in high demand internationally, particularly in regions where nonmetallic electrical conduit is widely accepted by code and frequently specified in projects.

Our inquiries and sales data also show that North America, the Middle East, and Southeast Asia are the main markets where customers request Schedule 80 more often.

🇺🇸 United States – Driven by NEC and UL 651

In the U.S., most commercial and industrial projects strictly follow NEC Article 352, which defines when Schedule 80 PVC must be used.

UL 651 compliance is a baseline requirement for all Schedule 80 conduit in the U.S. Projects often specify UL 651–listed products to ensure dimensional accuracy, mechanical strength, and sunlight resistance.

Distributors and contractors frequently inquire about Schedule 80 because inspections and AHJ approvals rely heavily on UL listing.

🇨🇦 Canada – CSA and CEC Alignment

Canadian projects also favor Schedule 80, especially in industrial and utility sectors. Products must meet Norma CSA C22.2 N.º 211.2 and typically also carry UL 651 listing.

El Canadian Electrical Code (CEC) requirements are similar to the NEC, making Schedule 80 the default choice when conduit is exposed to mechanical risk.

Many Canadian customers emphasize cold-weather impact performance, which is covered by UL 651 testing.

🌍 Middle East & Southeast Asia – Project Specification Driven

In regions such as the UAE, Saudi Arabia, Malaysia, and Singapore, demand is largely project-specification driven.

Large industrial, oil & gas, and infrastructure projects often request UL 651–certified Schedule 80 PVC. Even if local codes reference IEC or ASTM standards, international contractors tend to prefer UL-listed conduit for global compliance and ease of inspection.

Clients in these markets often ask for documentation, test reports, and compliance certificates before approving material supply.

💡 Why This Matters to Professionals

Understanding where Schedule 80 PVC is commonly used—and which standards those regions follow—helps professionals at all levels:

• Distributors stock the right products for their key markets

• Contractors ensure conduit meets inspection and certification requirements

• Project managers avoid delays caused by non-listed or non-compliant materials

By choosing UL 651–listed and CSA-certified Schedule 80 conduit, projects can achieve faster approvals, lower inspection risks, and better global acceptability.

5. Conclusión

Choosing between Schedule 40 and Schedule 80 PVC conduit is more than a material decision—it’s a judgment call that balances code requirements, environmental conditions, safety expectations, and cost-effectiveness.

As we’ve covered in this guide, Schedule 80 PVC conduit is required by the NEC in situations where the installation is exposed to physical damage, such as outdoor surfaces, industrial environments, or conduit near vehicles and machinery.

However, that doesn’t mean it should be used everywhere. Overbuilding can lead to higher costs, unnecessary complexity, and design inefficiencies.

On the other hand, Schedule 40 remains a valid, code-compliant choice in many scenarios, especially where the conduit is protected—such as inside walls, ceilings, or underground with adequate burial depth.

Tubo C is a professional PVC conduit supplier, providing high-quality Schedule 40 and Schedule 80 PVC conduits that meet international standards.

👉 If you’d also like to get a complete overview of PVC Schedule 40 conduit, we recommend checking out this article: “Schedule 40 PVC Conduit: Everything You Need to Know.”

Our products are designed to ensure safety, durability, and compliance for residential, commercial, and industrial electrical installations.

We sincerely hope this article helps you make the right choice when selecting conduit for your projects.

Wishing you success and smooth progress on every installation.

If you have upcoming project needs, feel free to reach out to us — we’re here to support you.

Preguntas frecuentes

1. Can I use Schedule 40 PVC for underground installations?

Yes, Schedule 40 is permitted underground as long as it meets proper burial depth and protection requirements (NEC Table 300.5). However, under driveways or heavy load areas, Schedule 80 is often recommended or required.

2. What is the difference in wall thickness between Schedule 40 and Schedule 80?

Schedule 80 has thicker walls than Schedule 40 for the same nominal size, which makes it stronger but also results in a smaller internal diameter. This can affect wire fill and heat dissipation.

3. Is Schedule 80 PVC conduit more difficult to install?

Yes, due to its increased weight and rigidity, Schedule 80 can be slightly harder to cut and handle, especially in tight or overhead spaces. Schedule 40 is lighter and more installer-friendly for many residential or interior applications.