Table of Contents

Toggle1. Introduction

🔌 Electrical conduit plays a vital role in protecting and routing electrical wiring in a wide range of building projects—from residential homes and commercial offices to large-scale industrial facilities.

🏗️ Whether it’s running power lines underground or organizing complex wiring in high-rise buildings, conduit ensures safety, durability, and compliance with electrical standards.

💰 When planning any electrical installation, one factor that can significantly impact your project budget is conduit pricing.

🧐 While conduit may seem like a straightforward product, its cost can vary widely depending on several technical and market-related factors—some of which are not immediately obvious.

👷♂️ This post is designed to help buyers—whether you’re an electrical contractor, project manager, distributor, or procurement officer—understand what truly drives the cost of conduit.

📦 We’ll walk you through the different types of conduit, key pricing factors such as material, size, and certification, and provide practical tips for getting the best value for your project.

🚀 Let’s get started.

2. Conduit Material Types Affect Conduit Cost

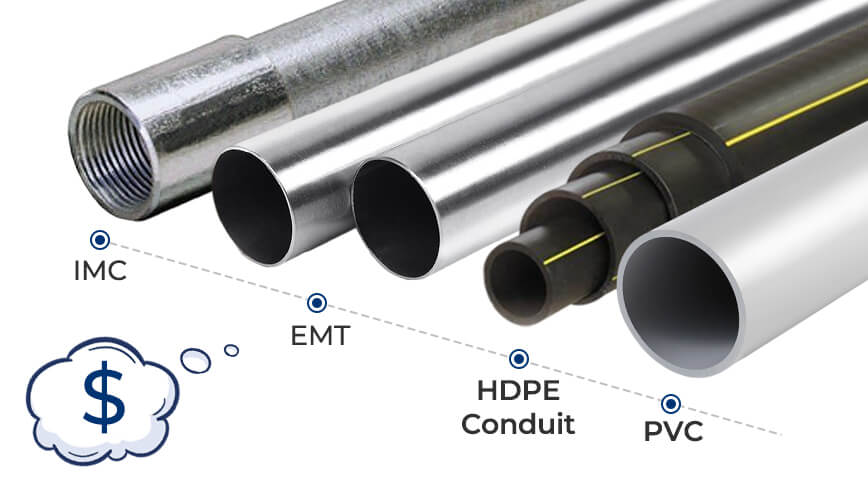

When it comes to conduit pricing, material type is often the first and biggest cost factor. Different conduit materials come with very different price tags—mainly because of how they’re made, how they perform, and where they’re used.

🧱 Just like how building a house with wood, concrete, or steel will give you very different budgets, the type of material you choose for your electrical conduit can greatly impact the conduit cost per foot.

The conduit material type you choose has a direct and lasting impact on overall conduit cost—not just at the time of purchase, but during shipping, installation, and long-term maintenance.

For example, PVC conduit is usually the most affordable option. That’s because plastic is cheaper to produce.

On the other hand, metal conduits—such as those made from steel or aluminum—are more expensive right from the start. Because metals like steel and aluminum cost significantly more than plastic as raw materials.

Some specialized conduit types, such as LSZH (Low Smoke Zero Halogen) or fiberglass-reinforced conduit, are even more expensive. These are designed for fire safety or chemical resistance and are priced accordingly.

3. Conduit Specifications and Certification Requirements Affect Cost

Conduit pricing isn’t just about what the pipe is made of—it’s also about what it’s certified to do.

Different countries and industries follow different conduit specifications and certification standards, such as UL 651 (United States), AS/NZS 2053 (Australia/New Zealand), or IEC 61386 (international).

Each standard sets out strict performance criteria—things like fire resistance, impact strength, UV protection, or chemical resistance.

And meeting those standards isn’t free.

To comply, manufacturers must often send products for third-party testing, provide full traceability of materials, and ensure consistent production quality.

It’s a bit like selling food: anyone can bake bread at home, but if you want to sell it in a supermarket, you need to pass health inspections, use approved ingredients, and follow labeling laws.

For example, conduits certified for underground or outdoor use must prove they can resist moisture, UV damage, and temperature extremes.

Conduits with a fire rating or low smoke certification must undergo even more rigorous lab testing.

All of that adds time, complexity—and cost.

So a conduit labeled with full UL or AS/NZS compliance will typically be more expensive than a non-certified alternative—even if they look the same.

👉 That’s why it’s important to check your project requirements before purchasing.

If your job site or local code demands certified conduit, skipping that step may not just be a risk—it could mean a failed inspection or even legal penalties.

In many commercial or public sector projects, using certified conduit isn’t optional—it’s mandatory.

✅ Bottom line: Certification drives up cost, but also ensures safety, performance, and compliance.

If your project involves regulated environments like schools, hospitals, tunnels, or infrastructure, certified conduit is not just worth the cost—it’s required.

4. Conduit Size and Wall Thickness Affect Conduit Cost

Another major factor in conduit pricing is size and strength—specifically, the outer diameter, the wall thickness, and the duty grade (light, medium, or heavy).

These details directly impact both material usage and performance—and therefore cost.

To put it simply: the bigger and thicker the conduit, the more it costs.

Because it’s larger, it uses more material and must meet stricter performance needs.

In many standards (like AS/NZS 2053), conduits are categorized by duty rating.

| Duty Rating | Abbreviation | Typical Use |

|---|---|---|

| Very Light Duty | VLD | Indoor, low mechanical stress |

| Light Duty | LD | General residential or light commercial |

| Medium Duty | MD | Standard installations, indoor/outdoor |

| Heavy Duty | HD | Industrial, underground, or exposed areas |

| Very Heavy Duty | VHD | Extreme mechanical protection needed |

⚠️ Tip: The thicker and heavier the conduit, the higher the cost—but also the better the protection.️

Wall thickness also affects how much raw material (PVC, steel, etc.) is used per meter, and how strong the conduit is.

Thicker conduits mean more weight, higher shipping costs, and in some cases, more effort during installation.

It’s also important to note that larger diameters multiply the cost quickly.

A 4-inch heavy-duty conduit doesn’t just cost twice as much as a 2-inch one—it can be four to five times more, depending on material and rating.

This is especially true for metal conduit, where both thickness and size drastically increase the price.

5. Environmental and Application Requirements Affect Conduit Cost

Where and how a conduit is used has a direct and measurable impact on its price.

While the base material plays a role, what really drives up cost in challenging environments is the need for extra protection—which usually means chemical additives, coatings, or engineering upgrades.

For example, a standard PVC conduit used indoors may only need to meet basic strength and insulation requirements.

But once you take that same conduit outdoors, the cost structure changes. Sunlight can degrade plastic over time, making it brittle and unreliable.

To solve this, manufacturers add UV stabilizers—special chemical compounds that protect against sun damage.

These additives don’t come cheap. They raise the material cost, increase manufacturing complexity, and require additional quality control.

The result is solar-grade conduit, which is specifically made to handle harsh outdoor conditions.

While it may be 15–30% more expensive than standard PVC, it lasts longer, reduces the risk of failure, and avoids early replacement—making it a cost-effective choice in the long run.

In underground or wet locations, conduits face moisture, pressure, and chemical exposure. This often calls for thicker walls, more corrosion-resistant materials, or external coatings, especially for metal conduits.

For instance, galvanized steel or coated aluminum costs more than raw material but is necessary to prevent rust and extend service life. Again, more protection = more cost.

In high-risk environments like tunnels, hospitals, or public buildings, fire resistance becomes a legal requirement.

In these cases, conduits must be made with flame retardants or low-smoke zero-halogen (LSZH) compounds.

These specialized materials are considerably more expensive, not just because of the chemical formulas involved, but also due to the extensive testing and certification they must undergo as we mentioned above.

In conclusion, the harsher the environment, the more advanced the conduit needs to be—and the more it will cost.

6. Procurement Strategy Influences Conduit Pricing

🛒 Beyond material and specifications, your procurement decisions can have a big impact on the final cost of conduit.

How much you order, who you buy from, and where they’re located—all of these influence the price per unit and the overall budget.

📦 Volume Matters: Small Orders vs Bulk Purchases

Just like buying in bulk at a warehouse store, ordering larger quantities of conduit usually results in lower unit costs.

Manufacturers and distributors often provide volume discounts, since it’s more efficient to produce and ship bigger batches.

On the flip side, small or one-off orders may come with higher prices per meter, setup charges, or even minimum order fees.

💡 Example: Ordering 500 meters of conduit might cost $2.00 per meter. But ordering 5,000 meters could bring that down to $1.50—or even lower.

That’s why, if your project schedule and budget allow, it often pays to combine orders or plan ahead to take advantage of bulk pricing.

🌏 Domestic vs Overseas Suppliers: It’s Not Just About Price

Overseas suppliers—especially in low-cost manufacturing countries—may offer attractive prices at first glance.

But keep in mind the true landed cost involves more than the product price.

- International shipping fees

- Customs duties and tariffs

- Currency exchange rates

- Longer lead times or potential delays

On the other hand, local suppliers may charge more per unit, but offer faster delivery, better after-sales support, and easier returns or replacements. In time-sensitive projects, that reliability can be worth the extra cost.

However, when managed properly, choosing the right overseas supplier can still contribute significantly to project success.

You’ll need a supplier who can meet your project’s technical requirements, maintain quality standards, and deliver on time, especially when long shipping times and customs processes are involved.

Because our products are regularly exported to global markets, we understand the importance of partnering with reliable, experienced manufacturers who know how to manage export logistics and comply with various international standards.

🌍 China, often referred to as the “world’s factory,” is a popular source for conduit manufacturing due to its mature supply chains, good quality and competitive pricing.

If you’re interested in sourcing from China, we’ve provide a guide for you👉 The Ultimate Guide to Choosing the Best Electrical Conduit Supplier in China.

7. Installation and Labor Impact the Total Cost of Electrical Conduit

While most people focus on the price of the conduit itself, installation costs can have just as much impact on your project’s overall budget. These costs aren’t always obvious at first—but they add up fast.

As we mentioned earlier, heavier materials like steel or thick-wall conduit are more difficult to transport, lift, and install. That usually means more workers, more equipment, or more time—all of which increase labor costs.

💡 For example, installing rigid steel conduit in a ceiling may require ladders, lifts, and multiple crew members.

In contrast, lightweight PVC conduit can often be installed by one person with simple tools.

Another key factor is conduit flexibility.

Flexible conduits are easier to route through tight spaces or around corners, which can save time.

Rigid conduit, while stronger, may require precision cutting, threading, or bending—adding hours of work on site.

Also, certain conduit types require extra installation steps.

For instance, metal conduit may need grounding and corrosion protection. And underground conduit might require trenching and waterproof seals.

🧰 Think of it like assembling furniture. One cabinet might cost $50 but take 3 hours and lots of tools to build. Another may cost $60 but snaps together in 20 minutes.

Which one is more “expensive”? It depends on your time and requirements.

8. Brand Reputation and Custom Features Affect Conduit Pricing

🏷️Not all electrical conduits are created—or priced—the same. Even when two products look similar on paper, their prices can vary significantly based on who made them and how they’re made.

⭐ Brand Reputation: Trust Comes at a Price

Just like in any other industry, well-known conduit brands often charge more than lesser-known ones.

Because with a trusted brand, you’re often paying for:

- Proven product performance

- Reliable quality control

- Comprehensive certifications

- Better customer support and after-sales service

🧃 Think of it like bottled water. One bottle may cost $1 and another $3—but the $3 brand might be known for its purity, taste, and safety record. You’re paying for peace of mind.

In large-scale or critical infrastructure projects, engineers and contractors may prefer well-known brands to reduce risk—even if the upfront cost is higher.

🧩 Customization: More Options, More Cost

If you need something beyond the standard conduit, expect the price to go up.

Customization typically includes:

- 🔴 Custom colors for easy identification on-site (e.g. red for fire, orange for communications)

- 📏 Non-standard sizes to fit unique installations

- 🧴 Private labeling or printing (like adding your logo, barcode, or spec info)

- 📦 Special packaging—such as export pallets, shrink wrap, or multi-language labeling

These extras might seem small, but they usually involve changes to production settings, special materials, or additional handling time—all of which increase cost.

📦 It’s like ordering a cake. A ready-made cake from the shelf is cheap. A custom cake with your company’s name, color theme, and dietary restrictions? That costs more—even if it’s the same size.

9. Conclusion

In summary, the cost of electrical conduit is influenced by multiple key factors, including material type, specifications and certifications, environmental requirements, supplier choices, and installation considerations.

Each of these elements affects not only the upfront price but also the overall project cost and lifecycle value. And therefore, before making a purchase, it’s crucial to evaluate the total lifecycle cost.

Balancing your project’s application needs, budget, and compliance requirements will help you make the most informed and cost-effective decision.

At Ctube, we specialize in supplying high-quality PVC conduit, UPVC solar conduit, and LSZH conduits and fittings.

Based in China, we offer a wide range of standard and customized solutions to meet diverse project demands.

With years of experience and participation in many successful projects worldwide, we understand what it takes to deliver reliable products on time.

Thank you for taking the time to read this guide. We hope this post is helpful.

Good luck with your project.