Introduction

If you are new to the field of electrical engineering, then you must have been confused by the word “schedule”. This post will compare and tell you all about schedule 40 and schedule 80, the two most common terms. We’ll discuss their specification standard, pros and cons, and also delve into how to choose them.

Schedule 40 and Schedule 80 PVC pipes are statistically proper for over 95% of projects in the construction industry. Schedule 40 and Schedule 80 pipes make up the majority of all pipes used in various industries. They are mass produced, cost-effective and easy to find. That’s why it’s important for you to know their differences and usages. Unfamiliar technical specifications can make it difficult to determine exactly what you need for your project and how to navigate all the different pipes.

Here’s a simple question: you need to move a heat pump about 15 feet from the original location. Can you run a PVC schedule 40 conduit on the brick wall to relocate the AC disconnect?

If you have no idea, you will get the answer after reading this post.

Key Points

1. what is Schedule 40 and Schedule 80?

2. what are the differences between them?

3. what are the specification standards to them?

4. what are the pros and cons?

5. what applications are they suitable for?

What is Schedule 40 and Schedule 80?

Schedule is a standard for measuring pipes and is proposed by ASTM (American Society for Testing and Materials). The standard applies not only to PVC pipes, but also to metal pipes. In this post, we will focus on PVC pipes.

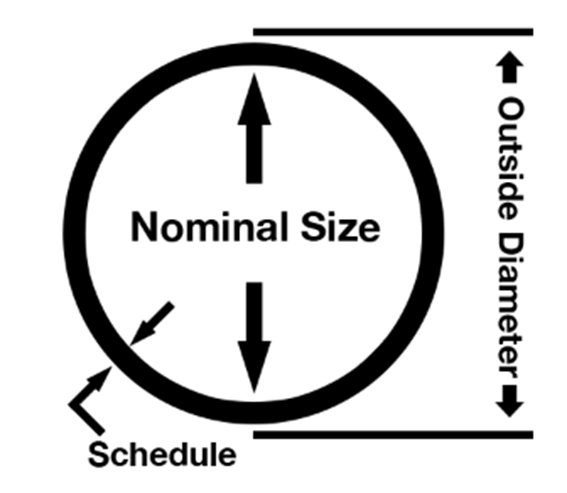

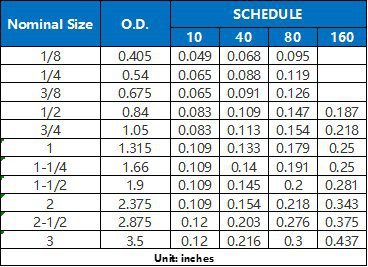

Schedule is used to indicate the wall thickness of a pipe. The larger the number following the Schedule, the thicker the wall of the pipe for the same outside diameter. These numbers range from 10 to 160, but 40 and 80 are the most commonly used. For example, a 1″ Schedule 40 PVC pipe has a minimum wall thickness of 0.133″ while a Schedule 80 has a minimum wall thickness of 0.179″. When we talk about wall thickness, we will definitely talk about 2 related words: Nominal Size and Outside Diameter. The relationship between them is as follows.

To give you a clearer and deeper understanding of them, please see the following data table for Schedules 10, 40, 80, 160 corresponding to Nominal Size and Outside Diameter.

As you can see in the table above, it is possible that Schedule 80 and Schedule 40 PVC pipe have the same outside diameter. This means that with the corresponding size fittings, Schedule 40 and Schedule 80 pipes can be used together if necessary. However, with the same outside diameter, the Schedule 40 inside diameter is larger than the Schedule 80 inside diameter because of its thinner wall. So the Schedule 40 pipe has less restriction on flow.

You are probably most familiar with Schedule 40 PVC pipes. They are commonly white that you see used for drainage around buildings and can be found at your local hardware store. This pipe is best suited for drainage, irrigation and other cold water systems. For works requiring higher pressures, Schedule 80 pipe is more suitable. In fact, Schedule 80 pipe is more often used for heavy-duty commercial and industrial applications. PVC pipes and fittings have their maximum pressure ratings so you know what they can handle. Usually, this is listed in pounds per square inch or PSI.

What are the differences between them?

From the above we already know that the wall thickness of Schedule 40 and Schedule 80 tubes are different. For a specified pipe size, Schedule 40 will have a thinner wall than Schedule 80. This means less material and weaker. Thicker pipes, i.e. higher gauge pipes, will have greater structural and chemical durability, stiffness, and resilience to strain and stress. From this point on we can see how they differ as explained below:

Withstandable Water Pressure

The wall thickness of a PVC pipe or fitting determines its durability. Schedule 40 PVC pipe is usually white in color and has thinner walls, so it can withstand less pressure than its counterpart. It is best suited for low water pressure applications.

In contrast, Schedule 80 PVC pipe is typically gray in color. It can handle higher water pressures and be well suited for industrial and chemical applications. For example, 1-inch Schedule 40 PVC pipe is rated at 450 PSI. But 6-inch Schedule 40 PVC pipe is rated at 180 PSI because although the wall thickness is the same. The greater capacity means it can handle less pressure. Similarly, 1-inch Schedule 80 PVC pipe is rated at 630 PSI, while 6-inch Schedule 80 PVC pipe is rated at 280 PSI.

Because the increase in Schedule 80 pipe wall thickness is internal. It reduces the inside diameter of the pipe. This reduction in inside diameter results in a slightly more restricted flow. It is not only able to handle higher PSI, but is also more resistant to bending and rupture than Schedule 40.

Cost

Pipe rated as Schedule 80 typically costs more to purchase than pipe components manufactured under Schedule 40. The thicker sidewalls of Sch 80 require additional material, as well as the inclusion of colorants (if applicable), resulting in its increased cost.

For pressurized liquid applications, Schedule 80 is usually a safer, more durable choice. If you are using PVC pipe and fittings for irrigation or home plumbing, then Schedule 40 PVC will probably get the job done and cost less. If you are using PVC pipe and fittings for industrial or chemical applications, you may need to use the higher cost Schedule 80 PVC pipe. Since these applications may result in higher pressures and thus put more stress on the pipe, the tougher Schedule 80 PVC is necessary.

If you are looking for Schedule 40 or Schedule 80 PVC electrical conduit pipe, we will provide it to you at the most competitive prices in the industry. Our value is to provide only the best pipes backed by product warranties and guarantees. Contact our team of professionals and experts today for your electrical solutions.

What are the specification standards to them?

According to the National Electrical Code (NEC), 352 gives specifications for the use of all electrical pipe, especially PVC electrical conduit pipe. 325 of the NEC contains the use of Schedule 40 PVC electrical conduit pipe.

– Use in walls, floors and ceilings

– Installed below grade

– Embedded in concrete

– Exposed to direct sunlight

The NEC 325 specification details the use of Schedule 40 PVC in these situations. if you anticipate using long 40 PVC electrical conduit pipe in these situations, familiarize yourself with the requirements of the NEC specification.

Schedule 80’s thicker wall provides more resistance to damage when installing conduit pipe in high flow or high hazard areas. In general, Schedule 80 PVC conduit pipe can be used in any situation where Schedule 40 conduit pipe is applicable. When used above ground, the NEC requires Schedule 80 PVC conduit pipe to be installed in areas where physical damage may occur and where additional wall thickness is required for safety reasons. (See NEC 352.10(F)).

For Schedule 40/80 pipes made of the same material, the installation process and specifications are the same. According to ASTM standards, different sizes of pipe with the same NPS have equal outside diameters. This provision allows pipes of different sizes to be joined together using the normal jointing method.

What are the pros and cons?

On the basis above we can conclude the pros and cons below.

Schedule 40:

– Lower price.

– Suitable for more residential plumbing and irrigation applications.

– Thinner wall thickness (0.154″ wall thickness for 2″ nominal pipe).

– Can handle pressures up to 280 PSI.

– Usually white, but not always.

Schedule 80:

– Slightly more expensive.

– Primarily used for chemical, industrial and manufacturing applications.

– Has thicker walls (0.218″ on 2″ nominal tubing).

– Can handle pressures up to 400 PSI.

– Usually gray, but not always.

What applications are they suitable for?

Determining which type of PVC piping to use on a job is usually specified by the architect or engineer. In some cases, it is necessary to know the local building code requirements for installing PVC pipe if there are no formal plans. In addition, you must install PVC pipes correctly to maintain the waterproof and insulating properties of PVC pipe. Each type of property, like residential, commercial properties, and industrial sites may have different requirements and uses, such as plumbing, landscaping, electrical, etc., all of which will affect the type of pipe you need.

Schedule 40 PVC Pipe Applications

Schedule 40 PVC pipe is one of the most used pipes today. Contractors, plumbers, landscapers and electricians rely on them for many projects because it is affordable while meeting their needs.

Depending on the inside diameter, it has a pressure range of approximately 130 PSI to 450 PSI, which exceeds the requirements of most residential water and drainage systems and is sufficient for irrigation and certain applications on commercial properties. This makes Sch 40 PVC pipe the right choice for

– Residential hot and cold water piping

– Landscape irrigation

– Swimming pool and spa design

– Buried or concealed electrical pipes

– Potable water supply

– Photography labs

– Water cooling systems

– Rainwater harvesting

– Aquarium or zoo plumbing

– DIY crafts

– Misting systems

Many people also use Sch 40 PVC pipes for structural support. Because of its light weight and stiffness, Schedule 40 PVC can provide an economical frame for structures such as tents or signs.

Applications for Schedule 80 PVC pipe

Schedule 80 PVC pipe is often an adequate alternative when Schedule 40 PVC does not provide a sufficiently high pressure rating. Its pressure ratings range from 220 PSI at the widest diameter to 850 PSI at the narrowest diameter. Sch 80 PVC pipes can also be useful in more exposed areas where people or machinery are likely to come in contact with the pipe, or when the pipe is buried under pavement with heavy vehicle traffic.

Applications using Schedule 80 PVC pipe include

– Commercial plumbing

– Chemical processing

– Manufacturing plant supply piping and sewer piping

– Agricultural irrigation

– Aquaculture

Schedule 80 PVC pipe provides the extra strength needed to withstand physical impacts when the placement of electrical wiring results in exposed pipe, especially in areas where foot traffic or activity occurs frequently in all weather conditions. Schedule 80 PVC pipe can withstand three times the external PSI of Schedule 40 PVC and has less risk of cracking or breaking. Electricians can use Schedule 80 PVC pipe in any of the same places as Schedule 40 – underground or wrapped behind walls and ceilings.

Conclusion

The content above is all about the comparative analysis and suitable applications of Schedule 40 & Schedule 80.

Let’s go back to that little question at the beginning: the answer is to choose Schedule 40 for the electrical pipe. Because it is cheaper and thinner than Schedule 80. It costs less and provides more room inside. You would need to be in a really bad area to have to use schedule 80 when you’re doing house improvement.

If we go back in time, we find that the word ‘Schedule’ is actually related to nominal pipe size. A nominal pipe size (NPS) is a set of North American standard sizes for piping used at high or low pressures.” Nominal” refers to pipe that is non-specific and identifies the diameter of the bore with a non-dimensional number (for example – 2″ nominal pipe” includes many varieties of pipe, the only standard is 2.375″ (60.3 mm) outside diameter). The specific pipe is identified by the pipe diameter and another non-dimensional number, and the wall thickness is called Schedule.

From the 1830s to the 1860s: Steam locomotives often exceeded 60 mph (100 km/h), but steel was not yet available. When engine designers needed more pressure, they wanted pipes that could withstand the higher and higher pressures that boilers could generate – but still had to use poor quality cast iron – so pipe works increased wall thickness by reducing the inside diameter of the pipes. This is because existing fitting and valve foundries don’t want to change their valve molds and cut new valve and fitting patterns, so the pipe OD needs to stay the same. Now, the pipe ID is usually – but not always – smaller than the “nominal”. The flow rate gets smaller, but the pressure gets higher. Designers put up with this discrepancy – they often don’t know what they’re really getting, because the instruments are still being invented, too.

Designers always wanted higher pressures and temperatures. Steel had better strength and fewer defects, so pipe walls could be thinner and still withstand high pressures. But now, pipe manufacturers don’t want to change their mills and equipment, so they require the pipe OD to remain the same. Therefore, the pipe wall becomes thinner (saving money by reducing the amount of steel used!) ), but the outside diameter stays the same – so the pipe inside diameter is “larger” than the nominal size. Designers are happy: they get more flow at lower weight, lower cost and higher reliability.

Thicker and thicker pipes reflect the development of social productivity and witness the progress of the times. We hope that after reading this post, your knowledge base will also become “thicker” and you will be invincible in your future work.

You can only see one thing clearly, and that is your goal. form a mental vision of that, and cling to it through thick and thin.

– Kathleen Norris